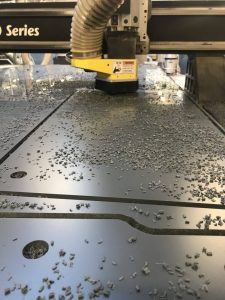

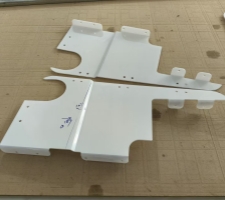

Lightweight and High Impact Resistance

Polycarbonate windscreens are widely recognized for their lightweight nature, providing significant weight reduction compared to traditional OEM glass. This weight savings translates directly into enhanced performance and fuel efficiency, making these windscreens a perfect fit for vehicles like race cars, UTVs such as the RZR XP 1000, and heavy equipment. The reduced weight of glass components also minimizes strain on the vehicle structure, contributing to a more efficient and smoother operation.

Beyond being lightweight, polycarbonate windscreens offer exceptional impact strength, making them highly resistant to damage from debris, harsh weather conditions, and daily wear and tear. This high impact resistance ensures they are capable of withstanding demanding environments, proving especially useful in applications like construction vehicles and off-road adventures.

Major companies like Amazon, EVRI, and The Hut Group are now using electric cargo bikes to deliver parcels in busy city areas. The reason is simple — they’re faster, cheaper, and greener than vans.

Scratch Resistance and Long-Term Durability

Thanks to advanced hard coating technology, polycarbonate windscreens are designed with superior scratch resistance and abrasion resistance. This makes them an ideal choice for critical areas such as rear windows, side windows, and rear windshields, where durability is key. The hardcoated polycarbonate surface significantly reduces the risk of scratches, extending the lifespan of the product and reducing the need for frequent replacements.

Additionally, the long-term durability factor of polycarbonate windscreens translates to lower maintenance costs over time. Whether you’re outfitting a UTV windshield or a pioneer 1000, this material ensures reliability and performance for years to come, even in challenging environments.

UV Protection and Anti-Fog Coatings

Polycarbonate windscreens come with built-in UV protection to shield against harmful UV rays, ensuring safety and comfort for drivers and passengers. This feature also prevents the material from yellowing over time, maintaining clarity and visual appeal. The inclusion of an anti-fog coating further enhances visibility, particularly in diverse weather conditions, making it ideal for vehicles like golf carts, UTVs, and polycarbonate boat windows.

These coatings are designed to perform in a wide range of environments, from humid coastal areas to cold mountain regions. For applications requiring frequent exposure to harsh weather, such as a half windshield for an off-road vehicle, these protective features ensure uninterrupted performance and visibility.