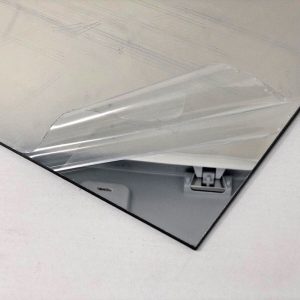

Polycarbonate Mirror Sheet

Polycarbonate Mirror Sheets are opaque and feature a shiny reflective finish, ideal for applications that require a mirrored surface with high heat resistance and shatter resistance. Materials such as Acrylic sheet (Plexiglass) or polycarbonate sheet serve as great alternatives to traditional glass mirrors. With their unbreakable properties, mirror sheets are perfect for use in bathroom mirrors, home gyms, dressing areas, and children’s play areas.

Features of Mirrored Polycarbonate sheet

High impact resistance (250 time stronger than glass)

More flexibility than glass, easy to fabricate and form for different shape

High Definition

Easy to cut, shape, drill

Shatter resistance

Customer color, size, shape, thickness

Light weight, half weight of glass

Can stand for high temperature

Anti-fog polycarbonate mirror sheet available

One-Stop process solution, like die cutting, forming, printing, CNC routing

Excelite Plastic Mirror Sheets Product Specification

Size: 1220*1830mm/1220x2440mm (Or customize your size)

Thickness: 0.8mm-6mm

Color: Silver mirror, Gold mirror, blue mirror, Rose gold mirror, Black mirror

MOQ: 50pcs per item, Free sample available

Key Differences of Acrylic Mirror vs Polycarbonate Mirror

When considering mirror sheets, glass mirrors are commonly known for their exceptional clarity, rigidity, and scratch resistance. However, they do have certain limitations, prompting the exploration of alternative materials such as plastic. The key focus here is the difference between polycarbonate (PC) and acrylic mirrors.

Clarity: Acrylic sheet has superior clarity, featuring a 92% light transmittance, while polycarbonate offers slightly lower clarity, with an 88% light transmittance.

Impact resistant: Polycarbonate is highly more stronger than acrylic, with 250 times more impact resistant than glass and 30 times impact strength than acrylic.

Processing: Acrylic is more rigid and needs to heated for molding. Polycarbonate is more flexible and allowing cold-forming

Applications: Acrylic sheets are opted for transparency and easy forming, making them ideal for applications like retail displays and fixtures. Polycarbonate sheets are extremely strong and heat/impact resistant, suiting them for applications requiring durability like bulletproofing or industrial safety guards. The choice depends on whether optical clarity or mechanical strength is more important.

Cost: There is no doubt acrylic is cheaper than polycarbonate. Polycarbonate is 35% much higher than acrylic mirror sheet. But also depends on the pc grade.

Processing mirror sheets to enhance the functionality and durability involves applying specialised coatings or treatments.

- Anti Scratch Coating

- Anti-Fog Coating

- Thermoforming

- CNC Routhing

- Die Cutting

- Silk screen Printing

Applications of Polycarbonate Mirror Sheet

Polycarbonate mirror sheet is a versatile material for indoor/outdoor and building projects.

- Commercial building – washroom mirror, observation mirror, fitness center mirror

- Cosmetic/Dental-compact mirrors, magnifying glassed and compact mirror

- Security / safety–Face shield, Mirror inspection, clear safety mirrors

- POP displays, jewelry box, sign, cosmetic display stand, end cap display stand

- Observation windows and equipment enclosures

- Machine guards window and sight glasses

- Automotive Aftermarket – Interiors and Accessories

- Monitoring of shops, showrooms, warehouses, offices, daycares or banks

Polycarbonate Mirror Sheet Application

Acrylic Mirror Sheet

Acrylic mirror sheet also named perspex mirror sheet, or PMMA mirror sheet.Acrylic mirror sheets share many similarities with polycarbonate mirror sheets but also boast distinctive features.

Polycarbonate Mirror Sheet

Excelite Polycarbonate Mirror Sheet is Stronger than Acrylic mirror sheet and stand for high temperature. It’s more safety.

Polycarbonate Convex Mirror

The Polycarbonate Convex Mirror is a specialised type of mirror that can provide a wide field of view. It can be used indoors or outdoors, offering unique safety and surveillance applications due to its ability to distort the mirror image and provide a panoramic view.

Anti-Ligature Mirror

An Anti-Ligature Mirror is designed to prevent the attachment of ligatures, providing safety in environments where self-harm risks are a concern. Constructed with extremely robust polycarbonate mirrors and solid surface surrounds, the single-piece encapsulation ensures a tough, high-grade finish suitable for secure settings.

Anti-Fog Mirror

An Anti-Fog Mirror is designed to resist condensation, ensuring clear visibility even in steamy environments like bathrooms or industrial settings. By employing a special coating or heating mechanism, it prevents fog from forming on the surface, providing an uninterrupted reflection at all times.

Two Way Mirror

Two-Way Mirror, also known as a see through mirror, it’s transparent from one side and reflective from the other, allowing observation without being seen.

Why EXCELITE Plastic

Excelite Plastic is a supplier that specialize in all kinds of polycarbonate sheets, polycarbonate coatings, polycarbonate parts, and components or after processing products made of polycarbonate. We have been in business for more than 15 years. EXCELITE’s polycarbonate mirror sheets can offer exceptional optical properties, mechanical strength, comfort and toughness. If you are looking for a mirrored surface which can fight off the damage caused by high heat, heavy impact and dangerous UV rays, do not hesitate to contact us to get more information on mirrored polycarbonate pricing.

Get A Quote Today

Bring Your Ideas to Life with Excelite Plastics.

Custom Polycarbonate Solutions Tailored for You.

Share Your Project With Us!

+86 135 8555 4902