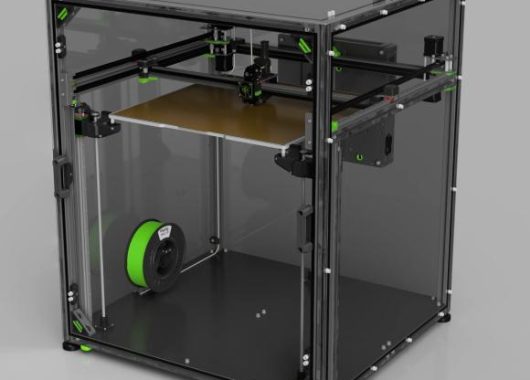

3D PRINTER ENCLOSURE

Excelite 3D printer enclosure helps regulate temperature, reduce noise, contain odors, and prevent dust contamination. Polycarbonate Covers improve print quality by minimizing warping and external interferences, ensuring successful and high-quality 3D prints.

What Is A 3D Printer Enclosure Sheet?

3D printer enclosure sheet is a protective covering used to enclose a 3D printer during the printing process. It is typically made of materials like acrylic(PMMA), polycarbonate, PETG, or PVC. The enclosure sheet should withstand high temperatures, maintaining a stable temperature inside the printer, reducing drafts and fluctuations that can affect print quality, and improving safety by containing fumes or particles released during printing. Additionally, enclosure sheets can help in noise reduction and provide a controlled environment for successful 3D printing.

Using a paper box for a DIY enclosure can pose safety risks, especially due to fire hazards associated with high temperatures from the 3D printer. The material isn’t designed to handle such heat, nor does it effectively manage fumes or particulate matter. Professional enclosures are made from materials that withstand high temperatures and are designed to ensure a safer and more stable printing environment. For better security and to minimize risks, investing in a purpose-built enclosure or using polycarbonate materials better suited for high temperatures and ventilation is advisable.

Importance of Using Enclosure Sheets for 3D Printing

Does the buzzing and beeping of your 3D printer bother you? Are you tired of dust constantly soiling the guides of your 3D printer? Annoyed of the smell of some filaments? Do you want uniform ambient temperature to minimize warping of your 3D printed parts?

The Benefits For Using Enclosure Sheets For 3D Printer

- Noise Reduction: Create a quieter and more peaceful working environment, especially in shared spaces or quiet settings.

- Dust Protection: Prevent dust and debris from settling on the printer components, including the guides.

- Odor Containment: Some filaments used in 3D printing can emit odors during the printing process. An enclosure sheet can help contain these smells within the enclosed space.

- Temperature Regulation: Enclosure sheets help create a stable and uniform ambient temperature inside the 3D printer enclosure. Solve the warping issues in 3D printed parts and enhance print quality and dimensional accuracy.

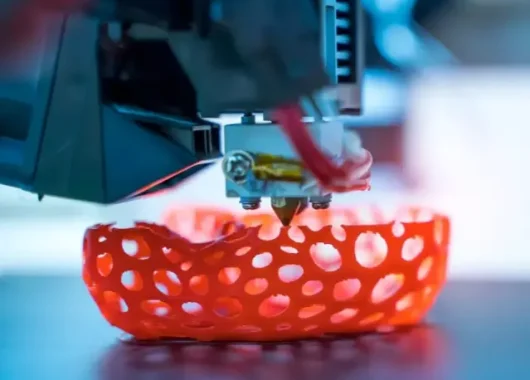

- Improved Print Quality: Reduced warping, consistent temperatures, and minimized external disturbances all contribute to higher-quality 3D printed parts.

Types of Materials Used in 3D Printer Enclosure Sheets

Acrylic Sheet

Advantages:

- Transparency: Acrylic sheets are transparent, allowing for easy monitoring of the printing process without the need to open the enclosure. This visual access enables users to check on print progress and troubleshoot issues without disrupting the printing operation.

- Durability: Acrylic sheets are known for their durability and impact resistance, making them a reliable choice for protecting the 3D printer and maintaining a stable enclosure structure.

- Lightweight: Acrylic sheets are lightweight compared to glass, making them easier to handle and install on the 3D printer enclosure. Their lighter weight simplifies the enclosure setup process and reduces the overall load on the printer frame.

- Easy to Cut and Customize: Acrylic sheets are relatively easy to cut and customize. We also provide fabrication and machining processing works for the sheets.

Considerations:

- Heat Resistance: While acrylic sheets can withstand moderate temperatures, they have lower heat resistance compared to materials like polycarbonate. Users should ensure that the enclosure setup and printer operation do not reach temperatures that could cause the acrylic to deform or warp.

- Scratch Sensitivity: Acrylic sheets are prone to scratching, so people should handle them with care during installation and maintenance. Using soft materials for cleaning and avoiding abrasive tools can help preserve the clarity and appearance of the acrylic sheet.

- Flammability: Acrylic is a flammable material, so it is important to consider fire safety measures when using acrylic sheets in a 3D printer enclosure. Avoid placing heat sources near the acrylic and ensure proper ventilation to minimize fire risks.

Polycarbonate Sheet

Advantages:

- High Impact Resistance: Polycarbonate sheets are known for their exceptional impact resistance, making them highly durable and capable of withstanding accidental impacts or rough handling.

- Excellent Clarity: Polycarbonate sheets offer excellent clarity and transparency, similar to glass, allowing for clear visibility of the printing process inside the enclosure.

- Superior Heat Resistance: Polycarbonate sheets have high heat resistance compared to acrylic and other materials, making them suitable for applications where elevated temperatures are involved.

- Lightweight and Easy to Handle: Despite their durability, polycarbonate sheets are lightweight and easy to handle, simplifying the installation process on the 3D printer enclosure.

Considerations:

- Cost: Polycarbonate sheets can be more expensive than acrylic or other materials used for 3D printer enclosures.

- Scratch Sensitivity: While polycarbonate is more scratch-resistant than acrylic, it is not entirely immune to scratches.

- Flammability: Polycarbonate is flammable and can release toxic fumes when burned.

You might also be interested in

Get A Quote Today

Bring Your Ideas to Life with Excelite Plastics.

Custom Polycarbonate Solutions Tailored for You.

Share Your Project With Us!

+86 135 8555 4902

Subscribe US!

Keep up to date with our latest offers, tips & new products!