Fire-Rated Polycarbonate Sheet

Excelite’s advanced Fire-rated Polycarbonate Sheets are a transparency fire resistant materials designed in fire safety construction and electrical applications. Engineered to withstand scorching temperatures of up to 240°C, our sheets take a quantum leap above conventional polycarbonate sheets, setting a new benchmark for safety, durability, and performance.

With excellent light transmission and high impact strength, Excelite flame resistant polycarbonate sheets provide you more choice. You can rely on them for a range of applications, from fire doors and fire screens to partition walls and equipment safety guards.

Features of Fire Rated Polycarbonate sheet

Key Properties

- Weather ability with UV protected coating

- Class V0 fire rating polycarbonate sheets & global FST compliant sheets available

- High impact and durability

- Scratch resistant

- Anti-vandalism, chemical & graffiti resistant

- Easy fabrication, cutting, bending and assembling

- Anti static, also support hot bending

- High light transmission for displays

- Customized solution

Technical specifications:

- Temperature resistance: up to 240°C (464°F)

- Flammability rating: UL 94 -V0/5VA

- Light transmission: Up to 88%

- Impact strength: 250 times that of glass, 30 times that of acrylic

- Available in different thicknesses: 1.9mm, 2.0mm, 3mm, 4.5mm, 6mm, and 9mm, max 24mm thickness

All About UL94

What is UL94 standard?

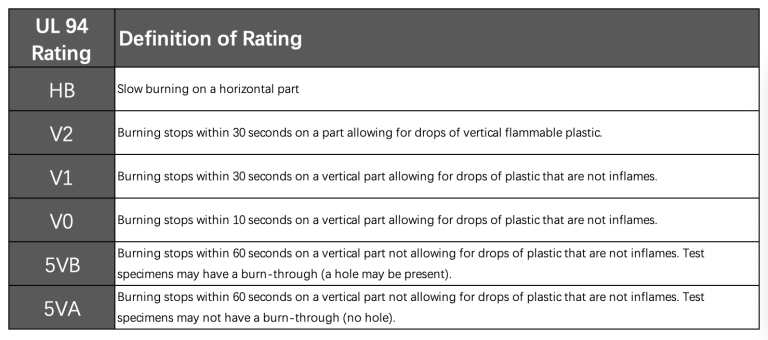

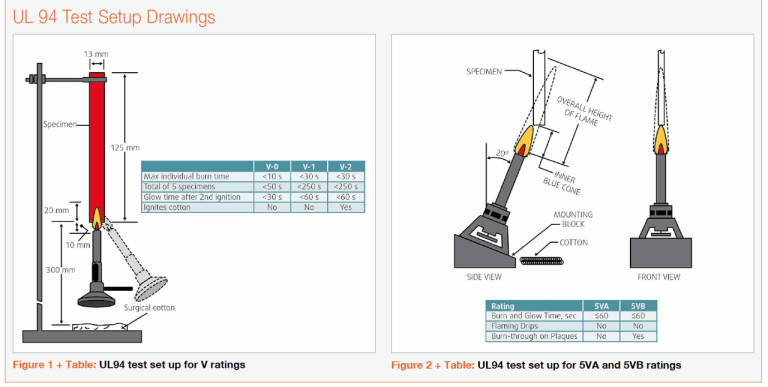

UL94 is a flammability test used to determine the flammability of plastics used in manufacturing equipment and appliances. UL 94 V-0 standard, a globally recognized benchmark for assessing the flammability of plastic materials. It is commonly used to assess products with special requirements for fireproof polycarbonate sheet, and the results serve as a fundamental indicator for choosing plastic material properties. Additionally, it is used to evaluate the dripping of plastics used in electrical and electronic equipment. The UL94 test categorizes materials into flame retardant grades HB, V2, V1, 5VA and V0 in decreasing order of performance.

UL 94 flammability testing is the plastic material recognition and subsequent list in the “Plastics Recognized Component Directory” (known as “Yellow Cards“).

Excelite’s 3mm clear flame-retardant sheet successfully cleared the UL94 5VA test. To attain a 5V classification, the test samples must not exhibit flaming or glowing combustion for more than 60 seconds following the fifth flame application. Additionally, they should not drip during the test. 5VA classification is the most difficult rating for polycarbonate plastic. Most of LEXAN FR series polycarbonate sheets are opaque, not transparent.

On this page, we specifically focus on polycarbonate flame-resistant sheets with a thickness of 1.9mm or more, excluding the UL 94 film. It’s important to note that these two undergo distinct testing methods. But Excelite 1.5mm polycarbonate sheet can achieve FAR25.853(a)(1)(ii)60s testing.

A great exciting news from Excelite

The latest flame retardant polycarbonate plastic from Excelite meets UL94-V0 rating at 1.9 mm, halogen-free formula, clear color. By comparison, most traditional flame retardant polycarbonates meet this key flammability rating at a thicker 3.0 mm. It’s noteworthy that this new grade achieves the UL-94 V0 rating at 1.9 mm while offering light transmission of nearly 90%, and only 0.05% haze.

**Check out an interesting video about UL 94 Horizontal & Vertical Flammability Tester, Flammability Test Chamber (Source: TESTEX Testing Equipment)

Applications of Fire Rated polycarbonate sheet

Excelite Fire Rated Polycarbonate Sheet is an optical grade transparent plastic sheet designed to meet International Building Code (IBC) Class A flammability requirements for interior wall and ceiling applications. Not only is it a good material option for wall and ceiling finishes but for barriers, dividers, and decorative panels.

- Construction industry:Façade cladding, skylights, lighting roofs, partitions

- Commercial Building, Train window, Metro

- Electronics industry: Screen, touch screen

- Medical industry: Hospital operating rooms, isolation wards, chemical laboratories

- Fire-retardant screening.

Fire Rated polycarbonate sheet Application

FR PC Sheet for EV Charging Stations

Excelite flame retardant sheet provides easy fabrication and handling properties, helping to achieve curved designs and displays options for the advertising or information panels for the EV charging stations.

Lighting Fixtures in Railway Vehicles

Flame-resistant polycarbonate sheets enhance the safety of lighting fixtures by reducing the risk of fire flaming in case of electrical malfunctions or emergencies. Excelite enhance the safety, durability, and performance of these essential components in railway vehicles and other modes of transportation.

Fire Rated Polycarbonate Enclosure is a specialized protective electrical and electronic components from fire resistance and safety in various applications. This type of enclosure is specifically engineered to withstand high temperatures and flames, making it suitable for environments where fire protection is crucial.

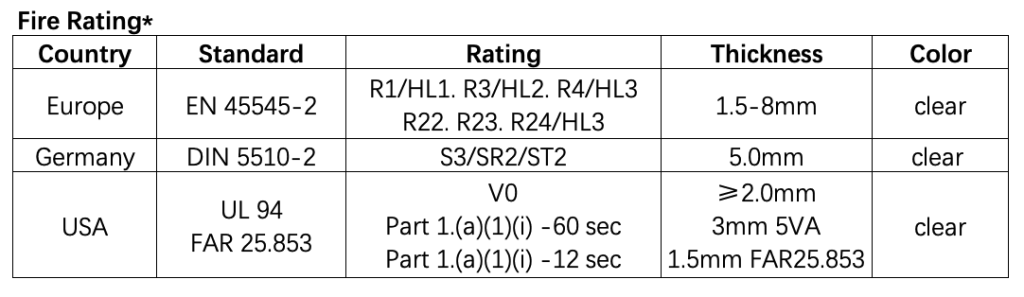

The differences between UL94, EN 45545, and DIN 5510 standards

The differences between UL94, EN 45545, and DIN 5510 standards in terms of fire protection requirements for plastic materials used in various applications are as follows:

UL94:

Scope: UL94 is a standard that sets fire protection requirements for the use of plastic materials in devices and applications, such as plastic casings, switches, and other electrotechnical components.

Focus: It primarily focuses on the flammability of plastic materials and categorizes them into different flame retardant grades (V2, V1, 5VA, V0).

Application: UL94 is commonly used in industries where fire safety is crucial, such as electronics, appliances, and consumer goods.

EN 45545-2 or FAR 25.853:

Scope: EN 45545-2 and FAR 25.853 are standards that specify fire protection requirements for materials used in railway vehicles (EN 45545-2) and aviation (FAR 25.853).

Focus: These standards emphasize the fire safety of materials used in transportation applications, including lamp covers, linings, and other components.

Stringency: EN 45545-2 and FAR 25.853 have specific requirements tailored to the unique fire safety challenges faced in railway and aviation environments, ensuring materials meet stringent safety standards.

DIN 5510:

Scope: DIN 5510 is a German standard that addresses fire protection requirements for materials used in railway vehicles.

Focus: It specifies fire safety standards for materials such as cables, wires, and other components to ensure they meet the necessary safety criteria in railway applications.

Comprehensiveness: DIN 5510 covers a range of fire safety aspects, including flammability, smoke density, and toxicity of materials used in railway vehicles.

FAQ

Most frequent questions and answers

Adding Flame Retardants to Polycarbonate: This method involves incorporating flame retardant additive particles, such as red phosphorus or aluminum hydroxide, into the polycarbonate resin. These additives can disrupt the combustion reaction of polycarbonate, thereby inhibiting the spread of flames. Polycarbonate sheets with these flame retardants exhibit significantly reduced burning rates.

Co-extrusion with Modified Flame Retardant Materials: This approach entails introducing modified copolymers, such as polystyrene or ABS, along with halogen-free or halogen-containing flame retardants, into the polycarbonate. Polycarbonate flame resistant sheets produced using this method can meet the flame retardant standard of UL94 V-0.

Whether through additive flame retardants or co-extrusion with flame retardant materials, polycarbonate can achieve excellent flame retardant properties. Depending on the specific requirements for flame retardancy and optical performance, we can select the most optimal solution to manufacture cost-effective flame retardant polycarbonate sheets.

The flame retardant polycarbonate sheets is not achieved through surface coating. Whether by incorporating flame retardant additive particles or using modified flame retardant copolymers, the flame retardant material are uniformly extrused throughout the entire cross-section of the sheet, rather than solely relying on surface coatings. This ensures a more reliable and durable flame retardant capability of the polycarbonate sheets.

Halogen-containing flame retardants release toxic hydrogen halide gases and other harmful substances during combustion, posing risks to human health and the environment. On the other hand, halogen-free flame retardants do not produce toxic gases during combustion, aligning better with environmental standards and safety requirements. In the majority of applications in the field of new energy vehicles, it is specifically emphasized that flame retardant sheets must adhere to a halogen-free formulation.

Get A Quote Today

Bring Your Ideas to Life with Excelite Plastics.

Custom Polycarbonate Solutions Tailored for You.

Share Your Project With Us!

+86 135 8555 4902