Plastic CNC Machining Service

ONE STOP PLASTIC MACHINING SOLUTION FOR YOU

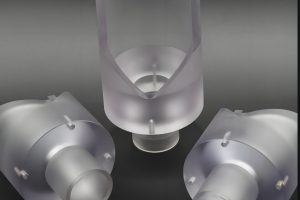

Excelite Plastic Specialized in engineering polycarbonate sheet and high-performance plastics in sheets, round rods, tubes, and more. Our extensive range of industrial plastics is complemented by our advanced CNC machining services, featuring state-of-the-art CNC cutting tools

What Is CNC Machining?

CNC machining is widely favored for both plastic and metal fabrication, particularly following the processing of polycarbonate sheets. CNC routing stands out for its exceptional precision, with error tolerances controllable within 0.05mm. At Excelite, we specialize in machining polycarbonate sheets in black or clear variants, ranging from 0.2mm polycarbonate films to super thick 100mm sheets, as well as from polycarbonate rods to tubes.

Polycarbonate offers remarkable clarity, shatter resistance, and reduced weight compared to glass, making it an ideal glass substitute. Moreover, it exhibits superior heat resistance to acrylic. Although CNC machining polycarbonate doesn’t inherently produce optically transparent parts, additional finishing steps are often necessary to achieve desired transparency.

Excelite CNC Machining Services include:

1. CNC Milling

2. CNC Turning

3. CNC Drilling

4. CNC Router

Start A New CNC Machining Quote

Polycarbonate and Acrylic CNC Milling Service

CNC Machining Turning can create plastic parts according to your design

Precise and Efficient CNC Drilling in plastic service

CNC Routing by a computer program to create complex shapes, patterns, or designs on various plastic materials

Advantages of CNC Machining on Plastics

- Faster Machining Speeds: Plastics are easier to machine compared to metals due to their lower hardness, which results in faster machining speeds and less tool wear .

- Cost-effectiveness: Once a design is programmed into the CNC machine, it can produce numerous copies of the same prototype with exact precision, ensuring consistency and reliability.

- Adaptability: CNC milling allows for easy design alterations without the need for new molds, providing flexibility in production processes .

FAQ

Most frequent questions and answers

You can pay Excelite through various convenient methods, including but not limited to:

1. Bank Transfer: You can opt to make payments to Excelite via bank transfer.

2. Paypal

Why Work With Us

With over 15 years of polycarbonate fabrication and machining experience, Excelite specializes in the fabrication of polycarbonate and acrylic sheet products, ensuring top-notch quality and precision. We are committed to providing the best manufacturing solutions tailored to your unique requirements.

Whether you have a detailed drawing or just an idea, our team of professionals is ready to turn your vision into reality. Enjoy the benefits of our services, including:

- In-house Design & Tooling

- Exceptional Accuracy (+/- 0.005″ Tolerances)

- Comprehensive OEM & ODM Services

- ISO 9001:2008 Certification

- Direct Manufacturer Advantage

We invite you to partner with us and experience a seamless, efficient, and quality-driven production process.

TAILORED POLYCARBONATE SOLUTION

Get a Quote Today

Looking to transform your vision into a tangible product?

At Excelite Plastics, we understand that every project is unique.