Laser Protective Polycarbonate Sheets

Excelite Laser protective sheet crafted from high-impact polycarbonate, our windows are designed to withstand high-power laser beams, offering unparalleled protection against a diverse range of laser types, including Nd:YAG and CO2 lasers. With an Optical Density (OD) that exceeds 6, these windows act as a formidable barrier against harmful laser radiation, ensuring the safety of both personnel and high-value equipment.

But we understand that laser protection isn’t the sole requirement. Our laser safety windows also deliver on performance, boasting exceptional Visible Light Transmittance (VLT) for crystal-clear visibility. This feature is crucial for operators who need to maintain precision in high-stakes environments, whether that’s in aerospace, healthcare, or advanced manufacturing sectors. Available in acrylic and custom sizes, Excelite’s laser safety viewing windows aren’t just a safety precaution; they’re an essential tool for maintaining both operational efficiency and stringent safety standards.

Features of laser protective Polycarbonate sheet

- High Impact Resistance:Laser protective polycarbonate sheets are made from a material that has a high impact resistance, making it ideal for applications where safety is a concern.

- Optical Clarity:The sheet offers excellent optical clarity and light transmission properties, which make it an ideal material for laser safety applications.

- Laser Protection:The light-absorbing materials in the sheet offers protection against different types of laser radiation, including Nd:YAG, CO2, and excimer lasers.

- Customizable:Laser protective polycarbonate sheets can be customized to meet specific design requirements, such as thickness, size, and color.

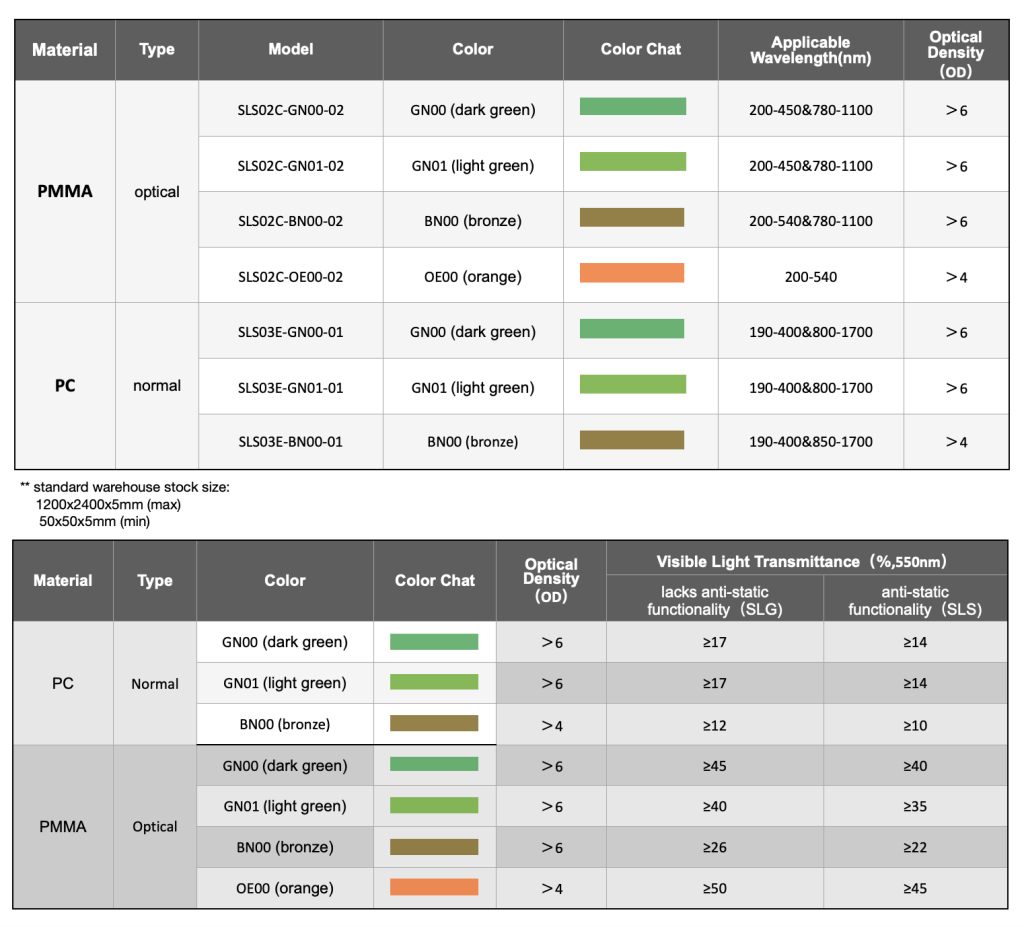

Selecting The Right Laser Shield

When Choosing Laser Shield, considering the following key factors:

- Working Laser Wavelength: The specific wavelength at which the laser operates.

- Laser Irradiance: The power or intensity of the laser beam.

- Optical Density: The protective plate’s ability to attenuate the laser’s output wavelength.

- Visible Light Transmittance: The requirements for allowing visible light to pass through.

- Damage Threshold: The level at which the protective materials can withstand laser exposure.

- Material Degradation: Any changes in the absorption properties of the material over time.

- Strength and Temperature Resistance: The material’s ability to maintain integrity under various conditions.

Our Performance Indicators

Optical Density (OD): Optical Density in Laser Safety (OD) refers to the measured attenuation of light at specific wavelengths. Each wavelength has a unique optical density, often expressed as a range for simplicity. Wavelength is the primary parameter for evaluating the required laser safety protection. The higher the OD value, the greater the protection ability of the laser protection product.

Visible Light Transmittance (VLT): VLT is a direct measurement of the user’s ability to see through the protective material under a standard background light source. While the protective material attenuates visible light, low transmittance can cause eye fatigue and affect color resolution, increasing safety risks in fields like electronics and chemistry. Generally, protective materials’ visible light transmittance decreases with increased optical density, so it’s essential to maximize VLT while meeting optical density requirements.

Damage Threshold of Protective Materials: To meet laser optical density requirements, protective materials must absorb or reflect high laser power or energy. Exposure to such high levels can cause damage to plastic materials, coating film layers, and even cracks in glass products. Therefore, it’s crucial to know the material’s maximum irradiance or exposure it can withstand without losing structural integrity. Understanding the time required to burn through the protective material at specific power or energy levels is also vital.

A Wide Range of Industrial Applications

1.Laser safety cover for equipment machine

Laser protective polycarbonate sheets can be used to create enclosures and covers for laser cutting and engraving machines, protecting workers and the surrounding environment from laser radiation.

2.polycarbonate laser guarding screen for Medical lasers

Laser protective polycarbonate sheets can be used to create shields or barriers that protect healthcare workers and patients from laser radiation during medical procedures.

3.Polycarbonate laser protective sheet Manufacturing

Laser protective polycarbonate sheets can be used to shield equipment and workers from laser radiation in manufacturing facilities, such as in the automotive or aerospace industry.

Laser Polycarbonate Sheet Application

Laser Protective Face Shield

Essential in medical, industrial, and research settings, this face shield provides a robust barrier against potential eye and skin damage for those working with lasers.

Laser Protective Filter

These polycarbonate sheets include a colored tint that enhances protection against specific types of laser radiation.

Laser enclosures are specifically designed to isolate various types of laser activities, including those involving excimer, argon, alexandrite, IPL, IR lasers, and KTP.

FAQ

Most frequent questions and answers

- Shields laser beams effectively, with optical density (OD value) above 6;

- Functional coating offers excellent friction resistance, chemical wiping resistance, and impact resistance;

- Complies with the EU RoHS directive for environmental protection

- Provides excellent electrostatic protection, with surface resistance between 1.0 ×10^0 and 1.0×10^9%;

- Nano-carbon material conductive system ensures long-term (permanent) anti-static performance;

- Absorbing protective material protects multiple specific wavelengths with higher visible light transmittance.

Suitable for various wavelength lasers’ processing equipment, laser marking system cover plates, laser management area partitions, mobile protective screens, etc.

Class 3 and Class 4 lasers’ direct and diffuse reflections are harmful, so corresponding laser protection windows must be installed. The GB7247 standard also mandates laser protection baffles for these classes. Installing protective windows on Class 2 laser processing equipment can further enhance operator safety.

Not necessarily. Common thicknesses are 5mm and 3mm, with similar parameters. Different thicknesses and sizes result from varying device window design requirements. Stacking two 3mm thick laser protection windows with the same parameters will increase the protection factor, but thickness alone does not determine protection parameters.

The choice of base material for laser protective windows significantly influences the protective performance of the finished window. You can contact us to find the difference with two material.

Under normal circumstances, if the equipment has been equipped with a laser protective window with appropriate parameters, the operator does not need to wear laser protective glasses. However, if discomfort occurs, it may be due to unsuitable parameters or light leaks in the equipment, and wearing laser safety glasses is still recommended. Wearing glasses is necessary when performing laser calibration and debugging in the equipment.

Absorption protection is all-round protection, absorbing and protecting light of corresponding wavelengths. It has no selectivity to the light source and can protect various diffuse reflection lights. Even if there are scratches, it will not affect the protective effect. Reflective protection, on the other hand, is selective to the light source and must face the protective surface for greater effect. Its practicality in an actual factory environment is limited.

No, most laser protective windows are made of organic materials and cannot be cleaned with high-concentration organic compounds like alcohol, acetone, or dichloroethane. If fingerprints or marks are present, use alcohol liquid below 2% or soapy water, and dry with a glasses cloth. Normal towels are not recommended as they may leave marks.

Get A Quote Today

Bring Your Ideas to Life with Excelite Plastics.

Custom Polycarbonate Solutions Tailored for You.

Share Your Project With Us!

+86 135 8555 4902