Applications of Acrylic and Polycarbonate Light Diffusers

Lighting Applications and Fixtures

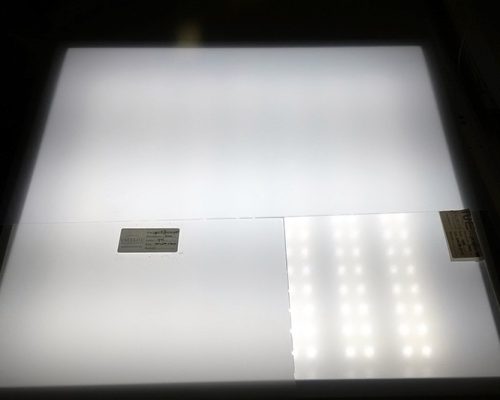

In lighting applications, both acrylic and polycarbonate materials offer distinct advantages. Acrylic light diffusers are widely used in lighting fixtures because of their excellent light transmission and ability to evenly distribute light. This helps in creating a soft, glare-free environment, making them a popular choice for indoor spaces such as offices and retail stores.

Polycarbonate light diffusers, however, are better suited for environments requiring high impact resistance. These include industrial settings or areas where the diffusers may be exposed to potential damage. Their durability ensures they remain intact even under challenging conditions, providing consistent lighting performance over time.

Specific Applications and Common Uses

The versatility of both acrylic and polycarbonate materials is evident in their wide range of applications. Polycarbonate, with its high impact strength and weather resistance, is commonly used for machine guards, riot shields, and bulletproof windows. These applications benefit from the material’s ability to withstand significant force while maintaining structural integrity.

Acrylic material, on the other hand, is frequently used in retail displays, display cases, and other aesthetic-focused installations. Its clear acrylic sheet format offers better clarity and a polished appearance, making it an excellent choice for showcasing products or creating visually appealing designs. Additionally, acrylic is often used in lighting applications that prioritize excellent light transmission and aesthetic appeal.

Factors to Consider When Choosing the Right Material

Weather and UV Stability

When evaluating acrylic vs polycarbonate for outdoor use, weather and UV stability are critical factors to consider. Polycarbonate materials are designed to offer superior UV stability, making them suitable for prolonged outdoor exposure. This ensures that polycarbonate sheets maintain their structural integrity and optical clarity even after years of exposure to sunlight and other weather elements.

Acrylic, while offering excellent light transmission and aesthetic appeal, may require additional UV protection for outdoor applications. Without proper treatment, acrylic sheets are more susceptible to yellowing and degradation when exposed to UV light. However, UV-resistant acrylic options are available, which can extend the material’s lifespan and maintain its appearance in outdoor settings.

Cost and Maintenance

Cost is another important consideration when choosing between acrylic and polycarbonate materials. Acrylic generally offers a lower cost compared to polycarbonate, making it a budget-friendly option for applications that do not require high impact resistance. Additionally, acrylic’s better clarity and aesthetic appeal add value in environments where visual presentation matters, such as retail displays or decorative installations.

Polycarbonate’s durability and ability to withstand high temperatures justify its higher cost, particularly for demanding applications. While polycarbonate may require less frequent replacement due to its long-lasting performance, its initial investment is higher. When considering maintenance, acrylic is easier to clean and maintain, thanks to its scratch resistance and smooth surface, while polycarbonate requires careful handling to prevent surface damage over time.

Laser Cutting vs CNC

When comparing acrylic and polycarbonate light diffuser sheets, consider not only optical and impact properties but also how each material is processed. Acrylic (PMMA) produces exceptionally clean, glossy edges when laser-cut, making it ideal for projects where edge appearance matters—such as decorative panels or light boxes with exposed edges. Polycarbonate (PC), on the other hand, is tougher and more heat-resistant, which makes it a better choice for CNC machining and applications requiring mechanical durability or complex milling.