Anti Fog Film

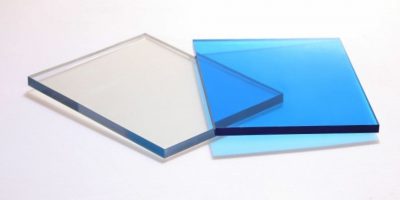

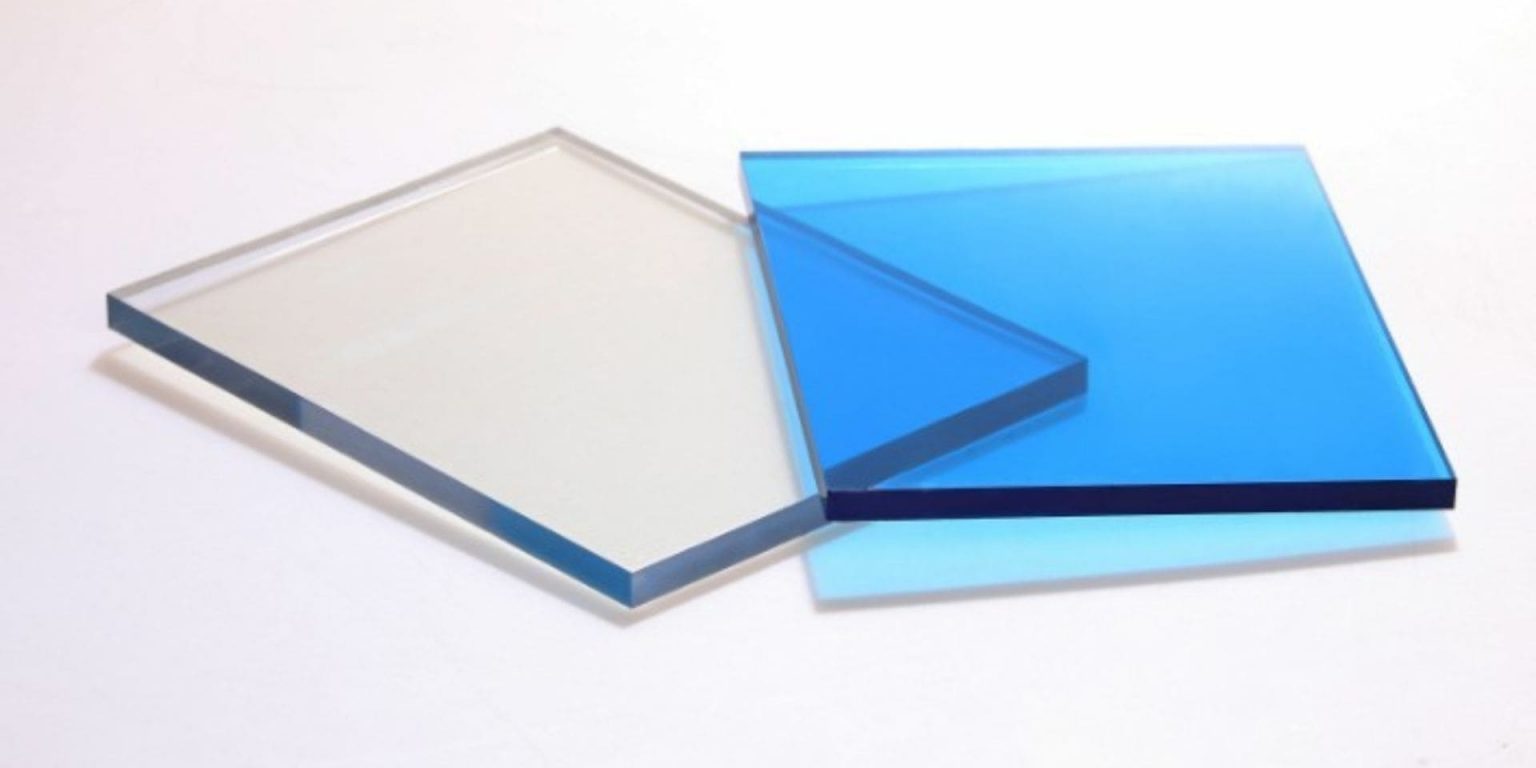

Premium Polycarbonate Film

Excelite Anti Fog Coating Technologies can deliver a variety of anti-fog coated films or sheets for many different applications, such as medical, industrial and commercial and safety protection or electronics applications.

Our anti-fog coatings can be used on a variety of different materials including polycarbonate sheet and films, PMMA films and sheets to special order parts and applications.

The coating will not saturate or fail under very humid environment and can retain anti-fog properties after repeated cleaning on the surface, it’s water washable.

Excelite Anti-fog product also has abrasion resistance, chemical and Impact resistance features,

Material: Polycarbonate sheet, PMMA sheet(Acrylic sheet), PET sheet

Thickness: 0.125mm-12mm

Size: 1220*2440mm or cut to size

testing for anti fog function

Markets Served

- Construction & Building

- (Conservatory/Greenhouses, Anti-fog Mirrors)

- Automotive & Transit (Aerospace, Bus/Coach, Motorcycle, Rail etc.)

- Commercial Freezer Display Cases

- Electronics (HUD, LED, Digital Billboard Displays)

- Medical & Chemical Safety protection

Anti-Fog Sheet Technical Data

| Product name: | Anti-Fog polycarbonate sheet | |||||

| Size | 1200㎜×2400㎜ Thickness:1mm-12mm | |||||

| Coating Specification | Formable Anti-Fog CoatingAbrasion Resistance Hard Coating | |||||

| Adhesion | 100% Cross hatch adhesion ASTM D3359 | |||||

| Coating Thickness | 9.0-15.0 Microns | |||||

| Anti-fog | >3 mins @ 60℃ and >98% RH | |||||

| TEST ITEMS | UNIT | SPEC. | RESULTS | TEST METHOD | ||

| Opticalproperties | Transmittance | % | Up 85 | 90.02 | Haze meterJIS K7105 | |

| Haze | % | Down 1 | 0.61 | |||

| Mechanicalproperties | Pencil hardness | – | HB | HB | Pencil testerJIS K5400 | |

| Taber | % | Haze | <10 | Taber CS10F/100 cycles at 500 g 5%ASTM D1044 | ||

| Cross cut | – | 100/100 | 100/100 | Cross cut test | ||

| Anti-fog | – | >3 minutes | @122℉ >98% RH | |||

| Environment properties | High temperature | – | Ok | External appearance :No changeHardness : No change | ||

| Hot Water test | – | Ok | ||||

| Thermal cycling | – | Ok | ||||

| Chemicalproperties | DI WATER | 25℃, 24hrs dipping | Ok | External appearance :No changeHardness : No change | ||

| Methanol | 100cycle rubbing | Ok | ||||

| Sulfuric acid (30%aq.) | Ok | |||||

| Acetone | Ok | |||||

Are you looking for face visors or shields that do not become foggy during temperature fluctuations?

Excelite brings you a comprehensive range of high-quality anti fog polycarbonate sheets and films for applications in a number of industries.

Certain products like face shields and visors are very important in industries like medical, electronics, military, etc. Hence, the surfaces of such protective gear must stay fog-free for ease of usage. At Excelite, we use the latest anti-fog technologies to create polycarbonate sheets that are suited for such applications.

Our expert team is well-trained in all aspects of anti fog polycarbonate. Hence, they can help you choose the ideal product as per your requirements.

Please request a quick quote today!

Why is Anti Fog Coating Required on Polycarbonate??

Fogging occurs naturally due to fluctuations in temperature and humidity. Fog consists of tiny droplets of water that condenses on any surface to form a blurry film. Anti-fog coatings on polycarbonate ensure visibility is not hampered due to fogging.

An anti-fog coating consists of a hydrophilic (water-loving) material that absorbs moisture in fog and converts it into an extremely thin film. This thin film allows light to pass through without distortion and thus eliminates fogging. Anti-fog coatings are hard coatings and are permanent. They do not strip away even after repeated washings.

Benefits of Anti Fog Polycarbonate Sheets

- Reduces excessive eye strain.

- Reduces risks of workplace injuries.

- Improves visibility during cycling, driving, or motorsport racing.

Special Features of Excelite Anti Fog Polycarbonate Sheets

- Extremely clear and transparent with no fogging.

- High dimensional stability even under fluctuating environmental conditions.

- Resistant to high impact and chemicals.

- UV-resistant hence does not fade or yellow.

- Compatible with mirror-coating materials.

- Can be combined with other technologies like anti-scratch, anti-static, anti-graffiti, anti-glare, etc.

- Low yield loss due to less debris during die-cutting.

- Can be printed on both sides.

- Highly flexible and versatile in use.

Applications of Excelite Anti Fog Polycarbonate Sheets

- Safety shields like helmet visors, military masks, sandblasting helmet guards, etc.

- Sportswear like ski goggles, motorcycle goggles, diving masks, etc.

- Medical safety screens like face screen guards, eyewear, etc.

- Personal eye wears like spectacles, sunglasses, etc.

- Skylights/roofs

- Greenhouses

- Automobile windshields, headlamps, and windows

- High-reflective mirrors

- Cold storage display cabinets

Why Use Our Anti fog Polycarbonate Film?

At Excelite, we use high-grade anti-fog coatings on our polycarbonate sheets. These anti-fog coatings consist of cross-linked hydrophilic polymers that give excellent anti-fog protection. These coatings are permanent and are not affected by changing environmental conditions like humidity, temperature, etc. Excelite anti fog polycarbonate sheets can retain their efficiency even after repeated washing or cleaning. They are highly durable and can last for ten years.

Customised Anti Fog Film

Excelite anti fog polycarbonate sheets and films come in a thickness range of 0.125mm-12mm with size 1200mm-2400mm. We can also customise the thickness and shape as per your requirements. We provide cut-to-size polycarbonate sheets with anti-fog coating that come in a variety of colours and tints. We can engrave, emboss, thermoform, and print your polycarbonate sheet as per your specifications.

Call us today to talk to one of our experts about anti fog polycarbonate products.