Yes, Polycarbonate tubes can be easily cut using standard tools. We also offer custom cutting services.

Yes, Polycarbonate tubes are UV stabilized, making them suitable for outdoor applications.

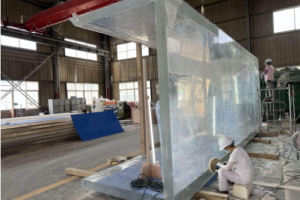

Polycarbonate is significantly safer than glass due to its high impact resistance. It is 200 times stronger than glass, making it shatter-resistant and ideal for applications where safety is a priority, such as in protective covers, machine guards, and structural components.

Yes, Polycarbonate tubes are highly durable and can withstand a wide temperature range from -40°C to 240°C, making them suitable for both indoor and outdoor environments, including areas with extreme heat or cold.

Polycarbonate Clear Round Tubes are commonly used in applications that require high strength and optical clarity, such as display cases, architectural elements, scientific instruments, protective covers, and decorative installations. Their high-gloss finish and durability make them ideal for both functional and aesthetic applications.

Yes, Polycarbonate tubes can be easily machined using standard tools. They can be cut, drilled, and formed without cracking or breaking, making them ideal for custom fabrication and structural applications.

Polycarbonate can be cut with a variety of saws using a fine tool carbide tip blade. If possible, a negative rake blade offers a smother cut.

Polycarbonate has good chemical resistance to many substances, but it is advisable to avoid exposure to certain chemicals, such as strong acids and bases, to maintain the material’s integrity and appearance.