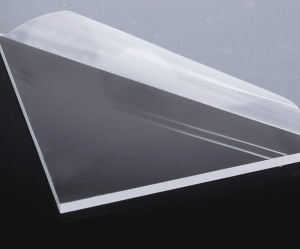

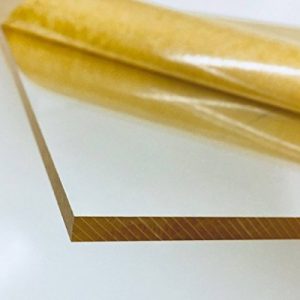

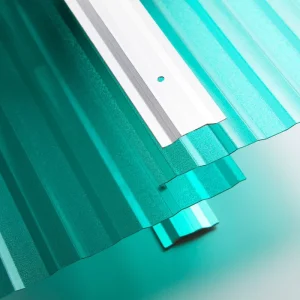

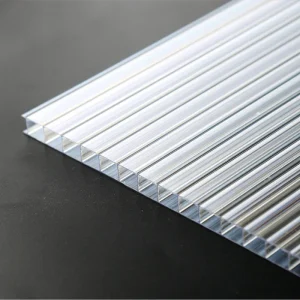

No, polycarbonate and Perspex (acrylic sheet) are not the same. While both are transparent plastic materials, polycarbonate is more impact-resistant, tougher, and flexible, making it nearly unbreakable. Perspex, also known as acrylic, is more rigid and has a higher clarity but is more prone to cracking and shattering under impact. Polycarbonate is better suited for applications requiring durability and impact resistance, whereas Acrylic is often chosen for its optical clarity and scratch resistance.