- HOME

-

- POLYCARBONATE

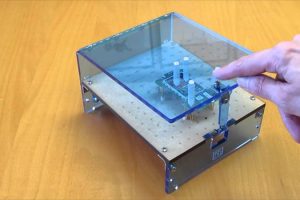

- ACRYLIC

-

-

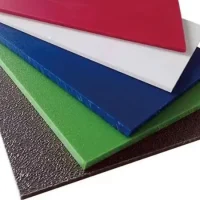

- ACRYLIC SHEETS

- Clear Acrylic Sheets

- Cast Acrylic

- Tinted Acrylic Sheets

- Anti-Fog Acrylic Sheets

- Acrylic Mirror Sheet

- Translucent Opal Acrylic Sheet

- Anti-Static Acrylic Sheets

- Anti Reflective Acrylic Sheets

- Anti-Graffiti Acrylic Sheets

- Anti-Glare Acrylic Sheets

- Fluorescent Acrylic Sheet

- Red Acrylic Sheet

- Opal & Matte Acrylic Sheets

- Opal Acrylic Sheet

- Matte White Acrylic Sheet

- Matte Black Acrylic Sheet

- ACRYLIC SHEETS

-

-

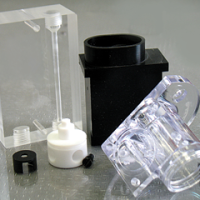

- FABRICATION

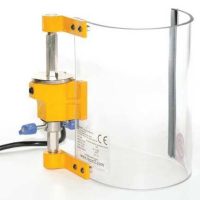

- APPLICATION

- BLOG

- ABOUT US

- CONTACT US