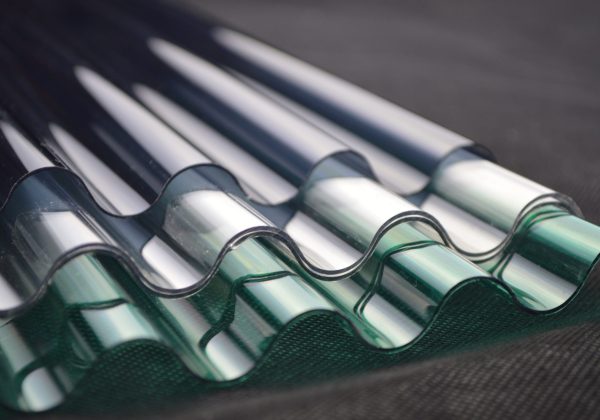

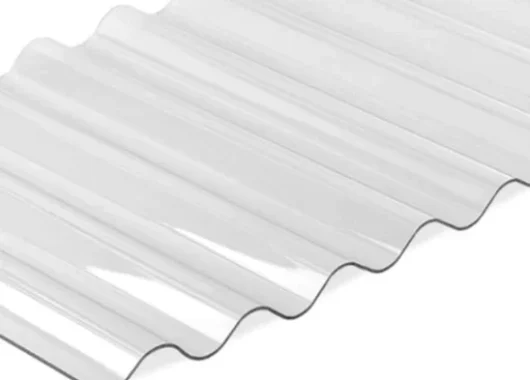

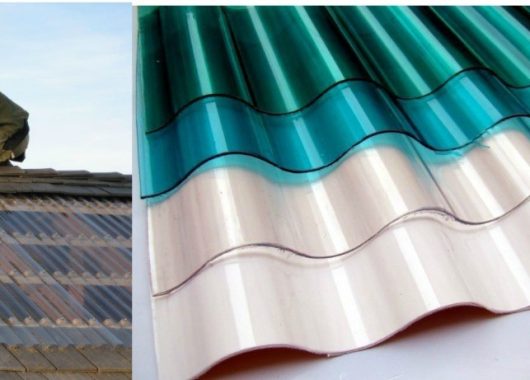

When it comes to roofing materials, there’s a wide array of options available, each with its own set of advantages and disadvantages. However, clear corrugated plastic, particularly in the form of polycarbonate sheets, stands out due to its unique combination of properties. Let’s compare clear corrugated plastic to other common roofing materials.

Clear Corrugated Plastic vs. Metal Roofing

Metal roofing is known for its durability and longevity. However, it doesn’t allow light transmission, which can make the interior of your structure dark. On the other hand, clear corrugated plastic offers high light transmission, allowing natural light to illuminate your space. Additionally, while metal roofing can be noisy during rain, clear corrugated plastic offers quieter performance.

Clear Corrugated Plastic vs. Fiberglass

FRP roofing panels are lightweight and relatively easy to install. However, they can become brittle over time and may not offer the same level of impact resistance as clear corrugated plastic. Furthermore, clear corrugated plastic provides superior UV protection compared to fiberglass.

Clear Corrugated Plastic vs. PVC

PVC roofing sheets are a cost-effective option and resist impacts well. However, they tend to have lower light transmission compared to clear corrugated plastic. PVC also doesn’t offer the same level of UV protection as clear corrugated plastic, which can lead to yellowing over time.

Clear Corrugated Plastic vs. Traditional Shingles

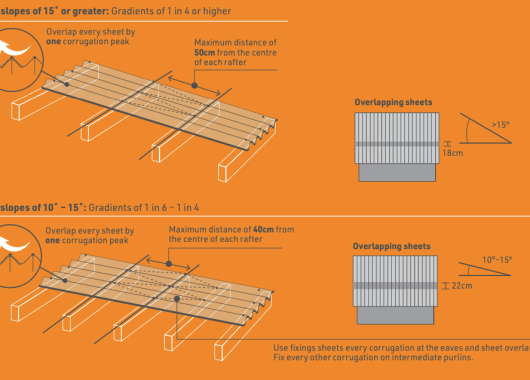

Traditional shingles, whether made from asphalt, wood, or slate, provide a classic look for roofs. However, they don’t allow any light transmission and can be more challenging and time-consuming to install. Clear corrugated plastic, on the other hand, is easy to install and allows natural light to pass through, making it an excellent choice for structures where light is desired.

Clear Corrugated Plastic vs. Acrylic Sheets

Acrylic sheets are another clear roofing option. While they offer good light transmission, they don’t have the same level of impact resistance as clear corrugated plastic. Acrylic can also scratch more easily and may not hold up as well in extreme weather conditions.

In conclusion, while each roofing material has its place, clear corrugated plastic offers a unique combination of light transmission, impact resistance, UV protection, and ease of installation, making it a versatile choice for a wide range of applications.