A Comprehensive Design Ideas for Polycarbonate Roofing

What Is The Polycarbonate Roofing?

Key Factors To Consider For Design Polycarbonate Roofing

When considering polycarbonate roofing for your project, there are several key factors to take into account to ensure a successful and effective installation. Here are some important considerations for designing polycarbonate roofing:

• Roof Shape and Slope

Determine the specific application for the polycarbonate roofing, such as a patio cover, greenhouse, skylight, awnings or canopies, verandas, balcony or commercial building. Different application may require different types of polycarbonate roofing sheets.

Consider the shape and slope of the roof to ensure proper water drainage and structural integrity. The roof design will impact the installation of polycarbonate panels and the amount of natural light entering the room.

- Polycarbonate Panel’s Type

Choose the right type of polycarbonate panel based on your requirements. For easy installation, consider corrugated polycarbonate sheets. For maximizing natural light, we suggest to use polycarbonate solid sheets. We also have the options for clear, tinted, or different colored panels based on your aesthetic preferences. Consider factors such as light diffusion, glare reduction when selecting colors and finishes.

- Climate and Weather Conditions

Take into consider the local weather elements, such as hail, wind, and snow loads, when selecting the thickness of the polycarbonate sheets. Thicker panels offer greater impact resistance and durability. UV protection coating is essential to prevent yellowing, and loss of transparency over time.

You also have options to insulation properties, flame resistance polycarbonate sheets depending on local regulations or safety requirements.

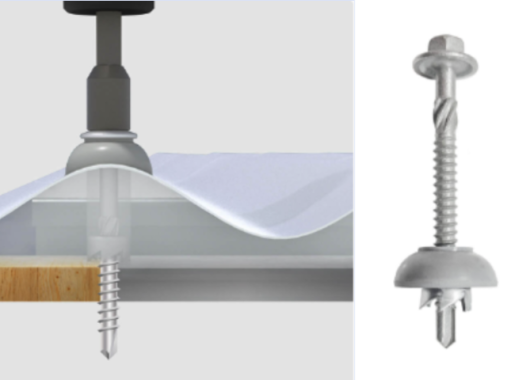

Installation of screw fastening

Excelite has rich experience in installing polycarbonate roofing systems. We provide the screw fastenings which create an expansion hole in a one-shot process, fixing polycarbonate skylights easily onto steel or timber substrates. Our polycarbonate roof screws can save 50% of labor time – create an expansion hole and fix sheets in one go. This efficient solution allows for the creation of expansion holes and securing of sheets in one seamless operation, enhancing the overall efficiency and effectiveness of the installation process. Proper installation is crucial for the longevity and performance of the roof.

Roof Support Structure

Evaluate the existing roof support structure to ensure it can accommodate the weight and load of the polycarbonate roofing panels.

For example,

Excelite polycarbonate fluted twin wall sheet-

6mm – 1.3kg/m2

8mm – 1.5kg/m2

10mm – 1.7kg/m2

Excelite polycarbonate solid sheet

Unit Weight (Kg/M2): 1.2Kg/mm/m2

4mm – 4.8kg/m2

6mm – 7.2kg/m2

Consider factors such as spacing of rafters, purlins, and trusses for proper installation.

Functionality

Determine the primary function of the polycarbonate roofing, whether it is to provide natural light, enhance aesthetics, improve energy efficiency, or protect against the elements. Design the roofing system to meet the specific functional requirements of the space.

Architectural Features

Incorporate architectural features such as curved polycarbonate sheets, domes, or custom shapes to create visual interest and uniqueness in the design. Explore creative design ideas that showcase the versatility of polycarbonate roofing.

Types Of Polycarbonate Roofing

There are several types of polycarbonate roofing available, each with its own characteristics and advantages. Here are some common types of polycarbonate roofing:

- Corrugated Polycarbonate Roofing

– Corrugated polycarbonate sheets are lightweight and easy to install.

– They provide good impact resistance and are suitable for a variety of applications, including roofing, skylights, and greenhouse panels.

– Corrugated sheets are available in clear, tinted, and colored options.

Multiwall Polycarbonate Roofing

– Multiple layers of polycarbonate separated by vertical ribs, also known as fluted hollow sheet, twin wall panel.

– They offer excellent thermal insulation properties and high impact resistance.

– Multiwall panels are commonly used for roofing, skylights, and architectural applications.

Solid Polycarbonate Roofing

– Solid polycarbonate sheets are flat and provide maximum clarity and light transmission.

– They are durable, UV-resistant, and offer good impact strength.

– Solid panels are ideal for applications where natural light is a priority, such as pergolas and sunrooms.

Embossed Polycarbonate Roofing

– Embossed polycarbonate sheets have a textured surface that diffuses light and reduces glare.

– They provide privacy and aesthetic appeal while still allowing light transmission.

– Embossed panels are often used for decorative purposes and in areas where light diffusion is desired.

These are some of the common types of polycarbonate roofing materials, each offering unique features and benefits for various applications. When choosing the right type of polycarbonate roofing for your project, consider factors such as light transmission, insulation properties, impact resistance, and design requirements.

Creative Design Ideas

Sloped or pitched roofs

The slope of the roof allows for efficient water drainage and minimizes the risk of water pooling, which provide the long lifespan of the roofing materials.

Balcony canopy, where a part of the balcony is sheltered by polycarbonate sheet roofing while the remaining area is left open and exposed. The frame material of balcony can be steel or timber.

Dual pitched roof, roofing option for covering expansive terraces.

Hipped roofs

Hipped roofs can be a great choice for a restaurant setting, where entirely enclosed in a transparent roof for balcony, offering both aesthetic appeal and practical benefits.

Countryside setting

Coastal areas

Rural retreats restaurants

Garden setting

Vineyards and wineries

History buildings

Lobby or verandah polycarbonate roofing

Its flexibility and ease-to-style, allowing it to fit into any interior you like. Its flexibility and durability make it a perfect choice for any room in your home.

Polycarbonate ceiling is also a good choice for you to walk move to another place.

Arched or curved polycarbonate roofs and domes

The use of curved polycarbonate panels in polycarbonate roofing design allows for innovative and creative possibilities, creating visually captivating structures with functional benefits.

Greenhouse polycarbonate roofing

Excelite Plastic provides twin wall polycarbonate sheet, flat polycarbonate rolls, polycarbonate embossed and corrugated sheet for greenhouse panels solutions. Greenhouses, also known as hot houses or glass houses, are specialized structures designed to create a controlled environment for growing plants, flowers, and vegetables. These structures provide protection against extreme temperatures, allowing tender or out-of-season plants to thrive in optimal conditions. A well-designed greenhouse serves as a hub where vegetation flourishes under controlled temperatures, humidity levels, and light exposure, facilitating healthy growth and cultivation.

Installation Tips

When installing polycarbonate roofing panels, it is important to follow instructions to ensure a secure and weather-tight installation. Here are some installation tips for polycarbonate roofing:

Choose the right polycarbonate sheets

Select the appropriate type and thickness of polycarbonate panels for your specific roofing application. Consider factors such as light transmission, insulation properties, and weather resistance when choosing the panels.

Measure and Cut to size

Measure the dimensions of the roof area where the polycarbonate sheets will be installed and cut the polycarbonate panels to size accordingly. Use a fine-toothed saw or a specialized cutting tool designed for polycarbonate to ensure clean and accurate cuts. Install support structures such as purlins, rafters, or framing members to provide a stable base for the polycarbonate panels.

Here we suggest to use our customized screw fasteners. It can easily fix polycarbonate skylight to steel or timber. It should prevent buckling or warping of the panels due to temperature changes.

Seal Joints and Edges

Seal the joints and edges of the polycarbonate panels with compatible sealants or flashing tape to prevent water infiltration and ensure a weather-tight installation. Pay special attention to areas where panels overlap or meet the roof surface.

TAILORED POLYCARBONATE SOLUTION

Get a Quote Today

Looking to transform your vision into a tangible product?

At Excelite Plastics, we understand that every project is unique.