3D Printing, also known as Additive Manufacturing (AM), is a technology that constructs three-dimensional objects by layer-by-layer deposition of materials. Unlike traditional subtractive manufacturing (e.g., cutting, drilling), 3D printing follows a “from nothing to something” approach, directly fabricating physical objects based on digital models (such as CAD files).

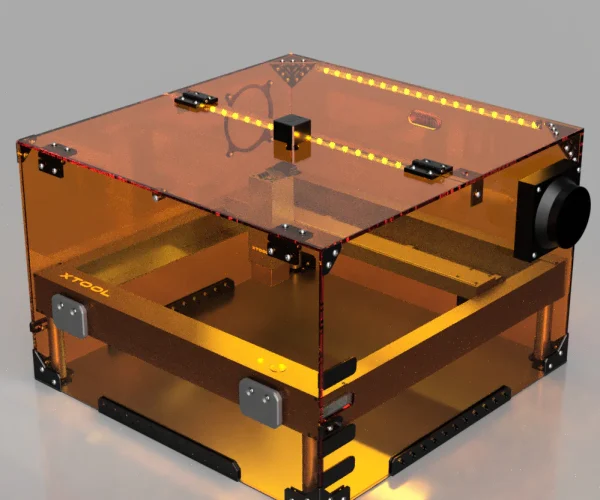

Acrylic 3D printer enclosure

Due to the low cost factor, general acrylic 3D printing covers are often used for home PLA/PETG printers. In addition, if you need to provide a high transparency and no violent collision environment, it is also very suitable for acrylic protective covers.

(1) High transparency and aesthetics

Light transmittance: 92%~93%, close to the clarity of glass, suitable for printing tasks that require fine observation (such as SLA light curing).

Surface gloss: easy to polish, can be made into a mirror effect, improving the appearance grade.

(2) Lightweight and easy to process

Light weight: density is 15% lower than PC, suitable for desktop printers.

Easy to cut: can be laser cut or drilled manually, DIY modification threshold is low.

(3) Cost-effectiveness

Low price: cost is only 1/3~1/2 of PC, suitable for consumer market.