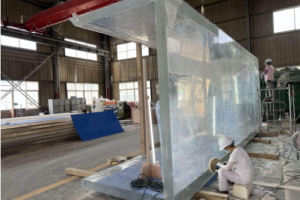

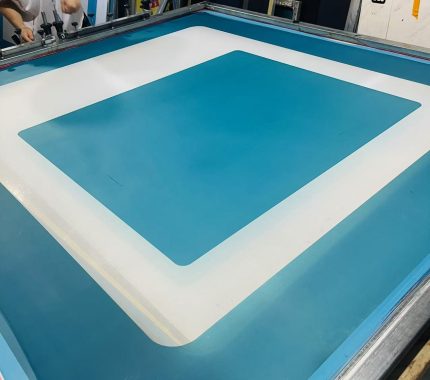

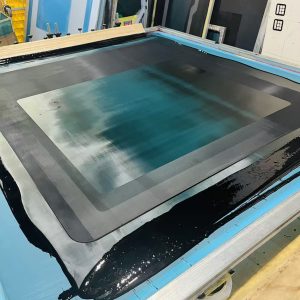

Silkscreen printing involves several printing processes to create high-resolution prints on various types of plastic materials. The technique requires mesh screens, a squeegee, and specialized ink. The mesh screen, containing the desired design, is prepared first. Then, the specialized ink is spread over the screen, and a squeegee is used to push the ink through the open spaces onto the plastic surface. This process is cost-effective and produces a wide range of printed images, showcasing precision and vibrant colors on polycarbonate and acrylic materials.