In an effort to manufacture quality and durable swimming screen pool enclosures, Excelite Plastics Ltd mainly uses solid polycarbonate sheets for all its products. Here we will discuss the difference of Solid Polycarbonate Sheet and Polycarbonate Hollow Sheet.

Basically, all our pool enclosures are manufactured from a combination of extruded aluminum rods and solid polycarbonate sheets.

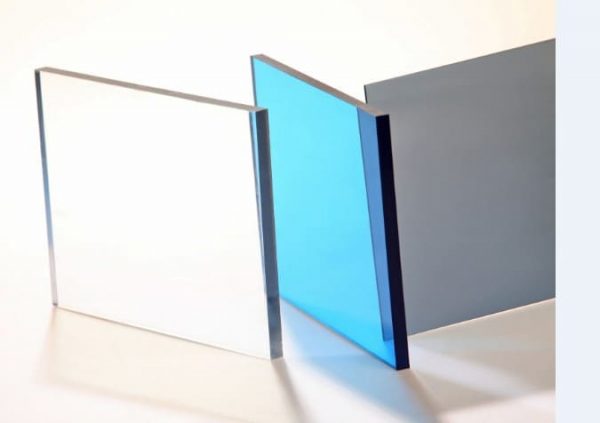

Solid Polycarbonate Sheets

This is why our enclosures are popular for:

- Ability to withstand strong wind speed – up to 230km/hr.

- Heavy loading – up to 900kg distributed within a radius of 1.5m

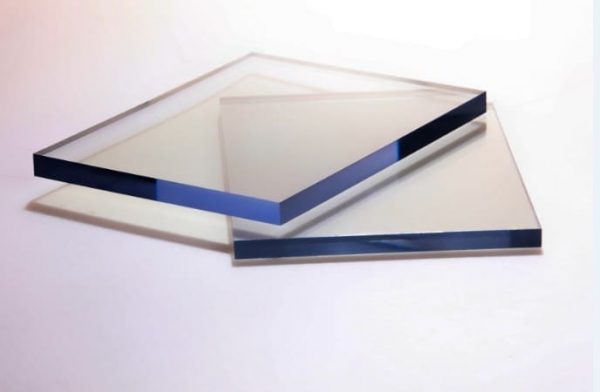

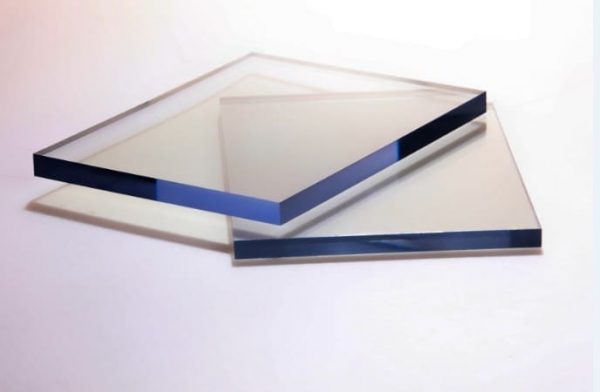

How does our solid polycarbonate sheets look like?

Transparent Excelite polycarbonate sheet

We use modern manufacturing processes to fabricate polycarbonate sheet into desired screen pool enclosures.

Our manufacturing process can transform polycarbonate sheet, to nearly any shape.

Therefore, we are able to manufacture screen pool enclosures with complex shapes.

But, what is the main difference between hollow and polycarbonate sheets?

Let’s start with:

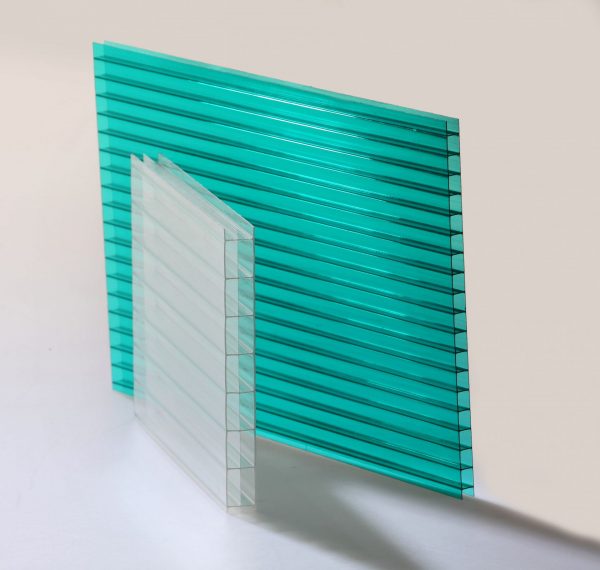

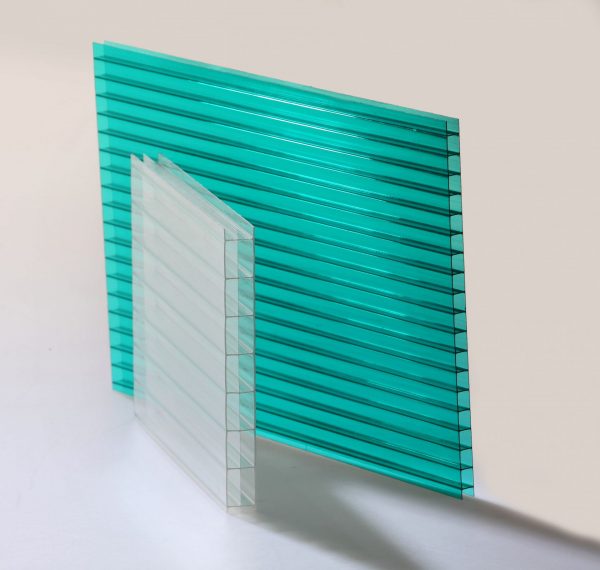

Hollow Polycarbonate Sheets

Structurally, Excelite hollow polycarbonate sheet has two layers with an air space between the layers.

Excelite hollow polycarbonate sheet

So, far it has become popular in a number of industrial and domestic applications such as greenhouse glazing.

This is mainly due to the lightweight.

This implies, one may not require strong structural reinforcement.

This will have some significant cost saving.

Furthermore, hollow polycarbonate sheets are also popular due to better insulation properties.

This is due to the air space that exist between the two sheets.

Air is a good insulator.

In many applications, the insulation property of hollow polycarbonate sheets is described in terms of its R-Value.

R-vale is a term used to describe the insulation property of a material.

As you can see from the above table, the R-Value mainly varies depending on the number of layers of the polycarbonate sheet.

Remember, the number of layers also forms the basis of classifying different types of hollow polycarbonate sheets.

That is, we can have:

- One-layer

- Two-layers

- Multiple layers

Normally, we may incorporate unique reinforcement between the layers to make it stronger.

That is, we may have intersecting sections from upper to lower layers.

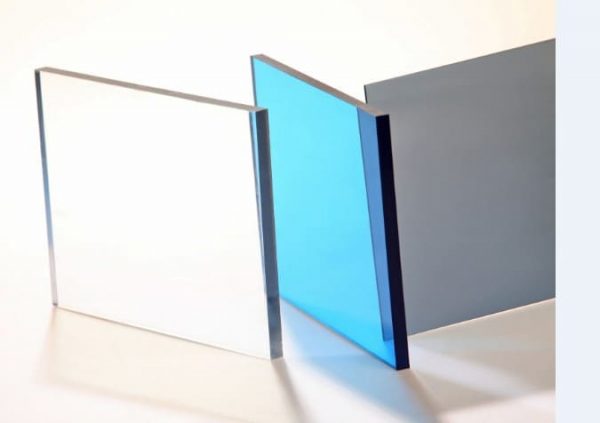

These polycarbonate sheets can also be tinted depending on the specific requirements of the end user.

That is, you may have:

Different colors of Excelite polycarbonate sheet

However, this reinforcement is not good enough for the hollow polycarbonate sheets to be used in the construction of screen pool enclosures.

This is why we still insist on using solid polycarbonate sheets for all our screen enclosures.

Remember, we are talking of a pool enclosure that should withstand a load of about 900kg per 15m radius.

Solid Polycarbonate Sheet for Screen Pool Enclosure

Structurally, Excelite solid polycarbonate sheet is a compact material.

That is, there are no air spaces between the cross sectional area of the sheet.

The solid polycarbonate sheet has excellent mechanical properties.

This makes it a perfect choice for the construction of screen pool enclosures.

It is extremely resistant to mechanical damage – nearly unbreakable.

This exceptional strength is actually the key selling point.

A solid polycarbonate sheet will remain in good shape even when subjected to extreme forces.

That is, it doesn’t matter whether it is wind at high speed (230km/hr.) or heavy load (900kg distributed within a 1.5m radius).

This explains the reason why excellent screen pool enclosures are highly recommended for snow prone areas.

Although solid polycarbonate sheets are not good insulators as hollow polycarbonate sheets.

Their ability to maintain swimming pool temperature is satisfactory enough.

So, the degree of insulation between the two polycarbonate sheets is not a key factor that can make one opt for a hollow sheet.

Moreover, another issue that has been raised in the recent past is the lightweight of polycarbonate sheets.

Well, hollow polycarbonate sheets are lighter than solid polycarbonate sheets.

Again, the eight here is not a fundamental aspect that can make one opt for hollow and not solid polycarbonate sheets.

Remember solid polycarbonate sheet is also considered a light material.

Normally, we use 8mm thick polycarbonate sheets for our screen pool enclosures.

However the end users are also at liberty to make their proposals based on what they consider to be the best.

As long as long as your screen pool enclosure design idea meets the quality threshold permitted by Excelite quality assurance team.

Below is a summary of all essential features of solid polycarbonate sheets and how they vary.

Conclusion

In short, all screen pool enclosures are manufactured from solid polycarbonate sheets.

This is mainly due to exceptional strength that exceeds that of hollow polycarbonate sheets.

The solid polycarbonate sheets are available in different thickness and tint.

You can choose one their meets your requirements.

Buy a Polycarbonate Swimming Pool Enclosure only $2999