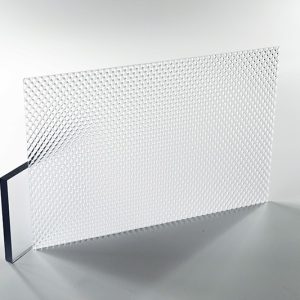

Thickness is an important factors influencing the diffusion effect of light and diffuser panels. Generally, the thicker the diffuser panel, the more reflection and scattering occur inside the material, resulting in a better diffusion effect. A greater thickness provides more scattering opportunities, allowing light to interact more fully with the surfaces inside the light diffusion panel, achieving a more uniform diffusion effect.

However, it’s not “the thicker, the better.”

When the thickness of the light diffusion panel is too large, the propagation path of light inside the panel becomes longer, increasing light loss and reducing light transmittance and intensity. Moreover, excessive thickness also adds to the weight and cost of the lighting diffuser.

Therefore, when selecting the thickness for your led diffuser sheet, you need to consider specific application requirements, including diffusion effect, light transmittance, cost, weight, and other factors. Typically, a proper thickness can be chosen based on the balance between the diffusion and light transmission and application.

Here are some commonly use thickness ranges for reference:

- 0.1 mm – 1 mm: Suitable for flexible light diffusion panels or applications that require thin designs. This range is applicable for products that need to be lightweight, flexible, and thin, such as mobile devices, tablets, handheld devices, etc.

- 1 mm – 3 mm: This is a common thickness range for light guide panels and is suitable for many indoor lighting, display devices, and backlighting panel. Panels within this range provide a good diffusion effect while maintaining a balance between light transmittance and weight.

- 3 mm – 6 mm: Suitable for applications requiring a higher diffusion effect and better light control. Light diffusion panels in this range are typically used in lighting devices, optical displays, LCD backlighting, and other fields, offering more even light scattering and superior optical performance.

It’s essential to note that the above thickness ranges are for reference only. The actual choice should be based on specific application requirements, material, optical design, and other factors.