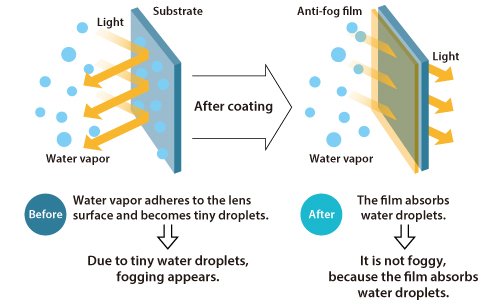

At Excelite, we’ve developed an extensive range of anti-fog polycarbonate products, designed to offer humidity resistance and work effectively across various temperature ranges. Ensuring clear visibility in a wide range of environmental conditions is a pressing need in various industries. Fog accumulation in either hot or cold environments may block light transmission and can result in undesired dripping, posing challenges to both safety and operational efficiency. With this in mind, Excelite brings you our comprehensive range of anti-fog polycarbonate sheets and films. These solutions employ advanced anti-fog coating technology that ensures persistent clarity, offering an excellent solution to the fogging issue.

Our anti-fog polycarbonate solutions are not only effective against fogging but also exceptionally durable, providing humidity resistance and performance across temperature ranges. They withstand varying environmental conditions and repeated cleanings, thereby providing long-lasting performance. Moreover, these products maintain excellent chemical and impact resistance, positioning them as robust solutions for demanding applications. We offer both permanent and single-use products to cater to various needs.