PLASTIC THERMOFORMING

Custom Thermoforming solution, large parts thermoforming

Excelite Thermoforming Service

Plastic thermoforming is a manufacturing process that applies vacuum or pressure to shape plastic sheets, commonly used across various industries. At Excelite, we focus on thermoforming polycarbonate and acrylic sheets for applications such as polycarbonate domes, skylights, boat windows, helmet visors, and riot shields.

Thermoforming methods include drape forming, heat forming, and vacuum forming, vacuum and drape forming being the most efficient and flexible. Polycarbonate sheets, compared to acrylic sheet, require more precise control due to their higher water absorption rate (0.3%), which necessitates drying before thermoforming to avoid bubbling.

Additionally, the hard coating on polycarbonate sheets may crack during heating, as it’s less flexible. If your project involves thermoforming, consult Excelite for a specially designed hard coating that can withstand the process.

Our capabilities

- Rapid thermoforming prototyping

- Rapid custom plastic moulding

- In house printing and finishing

- Large polycarbonate and acrylic parts thermoforming

- Thermoform-able coatings

- Multi-part Projects include edge scraping, silk-screening printing, assembly, bonding, polishing

Benifits of thermoforming service

- Versatility: Custom thermoforming can be used to create a wide range of shapes and designs, making it suitable for a variety of applications.

- Much lower tooling costs when compared to injection molding

- Quick process: Thermoforming is a quick process compare to injection moulding.

- Capability to do very large custom thermoformed plastic parts

- High-quality finishes: Thermoforming can produce parts with high-quality finishes, reducing the need for additional finishing processes

Disadvantages of Plastic Thermoforming

- Limited to certain shapes: While thermoforming is versatile, it can’t be used to create complex or intricate shapes.

Temperature Sensitivity: Polycarbonate has a higher thermal sensitivity compare to Acrylic sheet, which means that proper heating and cooling parameters must be carefully controlled during thermoforming to achieve consistent results and prevent material degradation.

Warping and Distortion: Polycarbonate has a relatively high coefficient of thermal expansion, which can result in warping or distortion of the formed parts, especially if not properly controlled during heating, forming, and cooling stages of thermoforming.

Brittleness: Polycarbonate is easy to scratch and crack under certain conditions. During the thermoforming process, the material may become stressed, leading to potential brittleness in the formed parts. Acrylic sheet is more scratch resistant compare to polycarbonate sheet.

Best plastic for thermoforming

As a clear plastic sheet, Polycarbonate sheet is one of the best plastic for thermoforming

Acrylic sheet can be formed into almost any shape, like Large Plastic Domes, Acrylic dome, Acrylic sphere, etc.

ABS

ABS is an opaque thermoplastic polymer that is commonly used in both thermoforming and injection molding manufacturing.

Types of Thermoforming Processes

- Vacuum thermoforming: Very affordable, quick manufacturing process, can create complex plastic shapes.

- Pressure Forming: Use air pressure to force the heated plastic sheet into the mold. It’s an affordable manufacturing process and can make large sizes.

- Drape Forming: Use gravity to drape the heated perspex sheet over the mold. Very affordable, quick manufacturing process

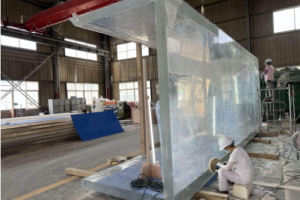

Large size thermoforming

Super large size Plastic thermoforming for boat window. 2000*3000mm

Pressure forming and CNC machining

Clear thermoformed kayak

Polycarbonate thermoformed Kayak,

Vacuum Thermoforming and pressure forming, CNC machining

Hard coated polycarbonate sheet, thermoforming, polycarbonate bonding, assembling

Security camera dome, replacement polycarbonate dome, acrylic dome with abrasion resistant coating

Motor helmet visor, Eye and face protection, PPE, face shields, with formable Antifog coating

Industrial equipment

Incorporated in machinery parts, fixtures, and toolings, such as jigs and custom components for manufacturing processes.

FAQ

Most frequent questions and answers

Thermoforming heats and shapes plastic sheets over a mold, making it more cost-effective for prototyping and low-volume production with cheaper, adjustable molds. It also allows for more material options and the production of larger parts with textured finishes.

Injection molding, while initially expensive due to complex molds, is highly efficient for large-scale production, quickly producing high volumes of precise parts.

The choice between them depends on project needs, with thermoforming being ideal for flexibility and size, and injection molding excelling in mass production. Both methods complement each other in offering versatile solutions.

Thermoforming is a versatile process used in many industries, from food packaging to aerospace and auto parts manufacturing. Since most industries work with thermoplastics at some point, understanding thermoforming is essential.

There are two main types of sheets: thin-gauge and thick-gauge. Thin-gauge sheets are commonly used for rigid, disposable packaging, while thick-gauge sheets have broader applications. These include durable surfaces for automobiles, window enclosures, building products, signs, and electronic equipment.

The possibilities for thermoformed plastic products are vast, but the process is not one-size-fits-all. The right material, techniques, and expertise are key to creating optimal results for each application.

Recent developments in thermoforming include advancements in non-composite sheets that add value to specific industries. Additionally, thick sheets are sometimes converted into composite sheets, resulting in thinner-walled parts that are ideal for weight-sensitive applications.

Excelite’s plastic fabrication center is located in Suzhou, China, supplying a wide range of polycarbonate sheets and offering plastic fabrication services globally, including to the USA, Mexico, Chile, UAE, France, Germany, and Singapore. We also have an overseas branch in Victoria, Australia, and provide polycarbonate sheets with nationwide shipping across the country.

People often ask which plastic is best for vacuum forming. Typically, vacuum forming uses thermoplastics, which become flexible at certain temperatures and solidify once cooled. One commonly used material is high-impact polystyrene (HIPS), known for its flexibility and ability to be molded into almost any shape.

Polycarbonate (PC) is another popular choice for vacuum forming. It’s extremely tough and resistant to flames, chemicals, and water, making it ideal for medical equipment and food manufacturing machinery. It’s also easy to mold, trim, and fabricate.

Acrylic (PMMA) is another widely used plastic for vacuum forming and thermoforming due to its versatility and ease of use.

One of the key advantages of vacuum forming is its cost-effectiveness. While the initial machinery investment may be significant, it is highly versatile and can produce a wide variety of products. Additionally, once molds are made, they can be reused repeatedly for mass production, making vacuum forming one of the most affordable methods of plastic fabrication.

Pressure forming provides a contrast to vacuum forming. The use of high pressure to push and pull the plastic tightly against the mold allows for greater precision, detail, and sharpness, while still being suitable for forming large plastic parts with ease.

Why Excelite?

With over 15 years of polycarbonate fabrication and machining experience, Excelite specializes in the fabrication of polycarbonate and acrylic sheet products, ensuring top-notch quality and precision. We are committed to providing the best manufacturing solutions tailored to your unique requirements.

Whether you have a detailed drawing or just an idea, our team of professionals is ready to turn your vision into reality. Enjoy the benefits of our services, including:

- In-house Design & Tooling

- Exceptional Accuracy (+/- 0.005″ Tolerances)

- Comprehensive OEM & ODM Services

- ISO 9001:2008 Certification

- Direct Manufacturer Advantage

We invite you to partner with us and experience a seamless, efficient, and quality-driven production process.

TAILORED POLYCARBONATE SOLUTION

Get a Quote Today

Looking to transform your vision into a tangible product?

At Excelite Plastics, we understand that every project is unique.