Basic facts about polycarbonate bending

When bending polycarbonate sheet, the surface is subjected to two forces – compressive and stretching force. These forces should be controlled carefully to avoid any cracks or fracture.

The amount of force required will depend on the stiffness of the polycarbonate sheet. Therefore, before the bending process begins, it is advisable to refer to the product datasheet to be sure of all these parameters.

This follows that, there are a number of precautions that you must have in mind during the process. These include:

1. High stress

When you subject a polycarbonate sheet to a high stress during bending, then chances of chemical stress cracking will be high. So, what should you consider to be high stress?

Well, this may vary depending on the thickness of a polycarbonate sheet. However, any pressure that is above 1500 psi is likely to cause high stress.

Again, polycarbonate is not inert. That is, it is affected by certain chemicals. Therefore, in aggressive environmental conditions, it should be subjected to less stress. You can also opt for polycarbonate sheets with chemical resistant coating.

2. Unprotected polycarbonate sheets

Normally, when bending polycarbonate sheet that is not protected, it must not be cold bent to a radius that is tighter than 100 times its thickness. Remember, the most crucial fact here is to reduce stress that can cause fracture or cracking.

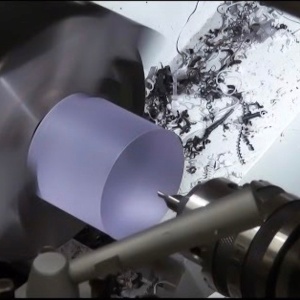

Classification of polycarbonate bending techniques

Broadly, this process is classified based on the temperature required during the bending process. That is, it can either be a cold or hot bending process. Of course, there are certain conditions that such a product must fulfill by all standards.

Take for example the hot bending process. Here, you will heat its surface evenly as you pre-dry the polycarbonate sheet to avoid formation of bubbles. Normally, such heaters require an electric current.

The bottom line is, the nature of the process involved will depend on customer requirements. The most important thing is the ability for companies to adopt a specific method that will guarantee zero errors.

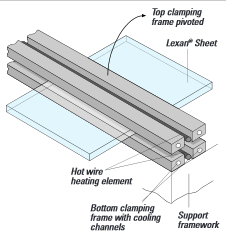

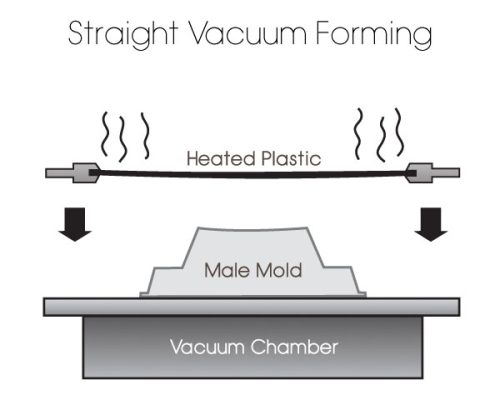

Hot line bending

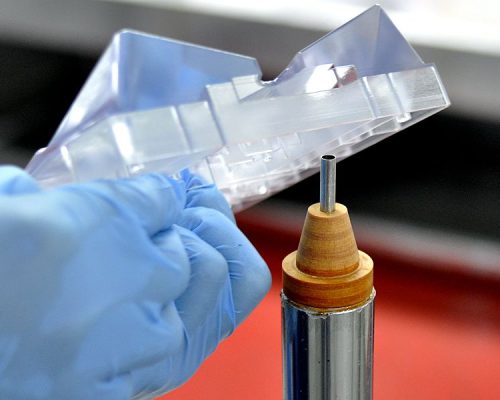

During hot line bending, a significant amount of heat is required to facilitate the process. It is commonly used to bend thick sheets more so, when an acute angle is desired.

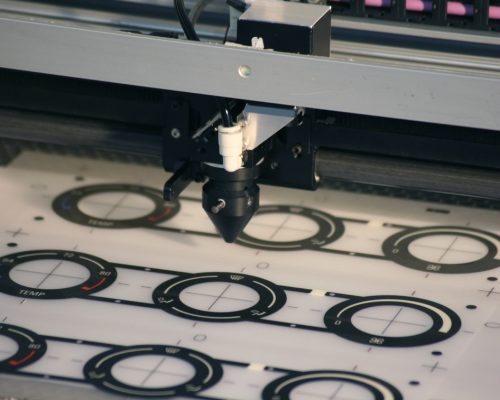

In this fabrication technique, the machine used has an electric heater. That is, during the bending process, polycarbonate sheet is heated along the line of the bend. Depending on the polycarbonate grade, the sheet can be heated on both sides.