Strength and Durability

One of the most significant differences between acrylic sheets and polycarbonate sheetslies in their strength and durability. Polycarbonate is known for its high impact resistance, being able to withstand impact 250 times more than glass, making it virtually unbreakable in most applications. This makes polycarbonate an excellent choice for applications where safety and durability are paramount, such as in bulletproof windows or protective face shields.

Acrylic, while not as strong as polycarbonate, still offers 10 times the impact resistance of glass. However, it is more rigid than polycarbonate and can crack under extreme impact. This makes acrylic more suitable for applications where high impact resistance is not a priority, but clarity and aesthetics are, such as in signage or display cases.

Environmental Impact and Sustainability

In today’s world, the environmental impact and sustainability of materials are increasingly important considerations. Both acrylic and polycarbonate have environmental impacts that should be considered.

Acrylic is a petroleum-based product and its production involves the release of harmful gases into the atmosphere. However, it is a durable material that can last for many years if properly cared for, reducing the need for replacement and waste. Additionally, acrylic can be recycled, although the process is not as widespread as for other plastics.

Polycarbonate, on the other hand, is a more energy-intensive material to produce. However, its superior durability and lifespan can offset this initial environmental cost over time. Like acrylic, polycarbonate can also be recycled, but the process is complex and not widely available.

It’s worth noting that both materials, when discarded, should be recycled or disposed of responsibly to minimize environmental impact.

Safety Considerations

Safety is another key factor to consider when choosing between acrylic and polycarbonate. As mentioned earlier, polycarbonate’s high impact resistance makes it a safer choice for applications where there is a risk of breakage or impact. Its shatter-resistant nature makes it ideal for use in safety glasses, riot shields, and other protective equipment.

Acrylic, while less impact-resistant than polycarbonate, is still considerably stronger than glass and can be a safer alternative in applications where glass might pose a risk of shattering. However, it can crack or shatter under high impact, so it’s less suitable for high-risk environments.

Versatility and Applications

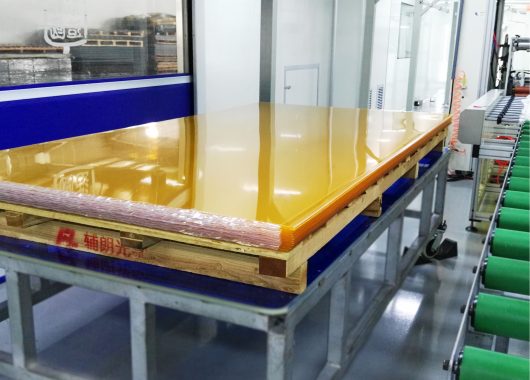

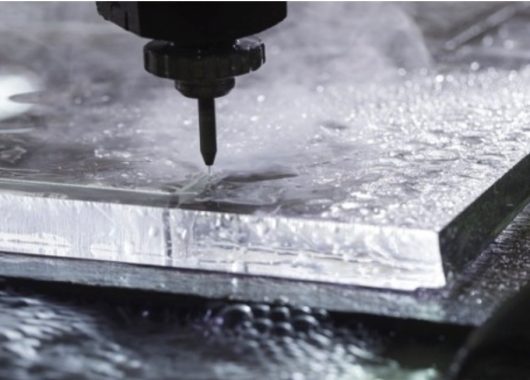

Finally, the versatility and wide range of applications of both acrylic and polycarbonate further highlight their unique properties. Acrylic’s superior clarity and gloss make it ideal for use in signage, displays, and light fixtures. Its ease of fabrication and ability to be easily cut and polished also make it a popular choice for DIY projects.

Polycarbonate’s high impact resistance and heat resistance make it suitable for a wide range of applications, from bulletproof windows to electronic components. Its flexibility also allows it to be formed into complex shapes, making it a versatile material for various industries.

In conclusion, the choice between acrylic and polycarbonate will depend on the specific needs and requirements of your project. By understanding the unique properties and advantages of each material, you can make an informed decision that best suits your needs.