FAQ

1. What are the advantages of using clear roofing made of polycarbonate?

Clear roofing made of polycarbonate offers several advantages. It allows natural light to filter through, creating a bright and inviting space underneath. It’s also highly durable and resistant to impact, making it a long-lasting roofing solution.

2. Can I use corrugated sheets for my pergola roof?

Yes, corrugated sheets made from polycarbonate are an excellent choice for a pergola roof. They offer a unique blend of durability, light transmission, and aesthetic appeal, making them ideal for this application.

3. Do I need to use silicone when installing polycarbonate roofing?

Yes, using a silicone sealant can help ensure a watertight installation. However, it’s important to use a silicone product that’s compatible with polycarbonate to avoid any potential damage to the panels.

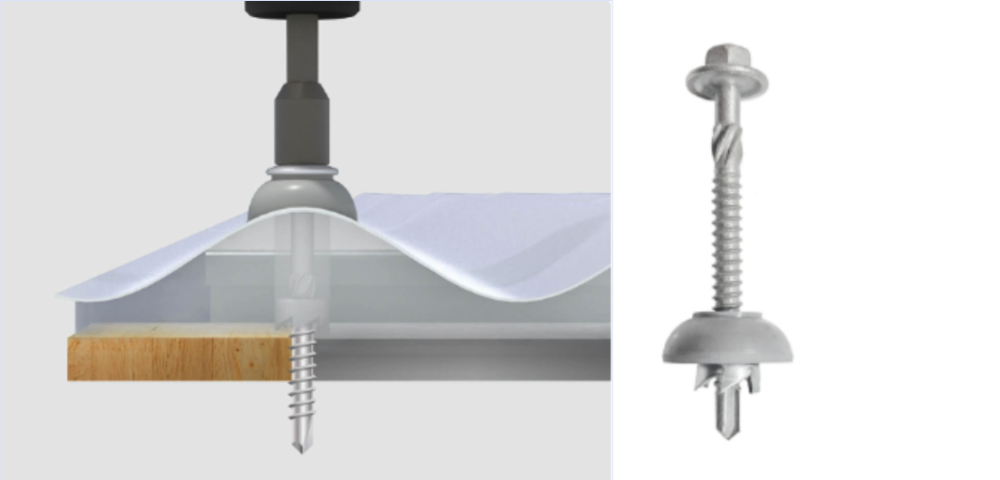

4. Is pre-drilling necessary when installing polycarbonate roofing?

Yes, pre-drilling is recommended when installing polycarbonate roofing. This helps to prevent the material from cracking or splitting during the installation process.

5. Can I use polycarbonate roofing as an alternative to metal roofing?

Yes, polycarbonate roofing can be a great alternative to metal roofing. While metal roofing is known for its durability, polycarbonate offers additional benefits such as light transmission and impact resistance.

6. What is the ideal roof pitch for installing corrugated roofing made of polycarbonate?

The ideal roof pitch for installing corrugated roofing made of polycarbonate is typically a minimum of 5 degrees. This helps to ensure proper water runoff and prevents any potential issues with water pooling on the roof.

7. Can I use plastic roofing for my pergola?

Yes, plastic roofing, particularly polycarbonate, is a popular choice for pergolas. It’s durable, allows light through, and can withstand various weather conditions, making it a practical and attractive option.

8. What is the warranty on polycarbonate roofing panels?

The warranty on polycarbonate roofing panels can vary depending on the manufacturer. However, many high-quality polycarbonate roofing products come with a warranty of at least 10 years.

9. What are purlins and why are they important in polycarbonate roofing installation?

Purlins are horizontal beams that are used to support the roofing panels. They are crucial in polycarbonate roofing installation as they provide the structure that the panels are attached to.

10. Can I use PVC instead of polycarbonate for my roofing project?

While PVC can be used for roofing, it doesn’t offer the same benefits as polycarbonate. Polycarbonate is more durable, has better light transmission properties, and is more resistant to impact and UV radiation compared to PVC.