Adding Flame Retardants to Polycarbonate: This method involves incorporating flame retardant additive particles, such as red phosphorus or aluminum hydroxide, into the polycarbonate resin. These additives can disrupt the combustion reaction of polycarbonate, thereby inhibiting the spread of flames. Polycarbonate sheets with these flame retardants exhibit significantly reduced burning rates.

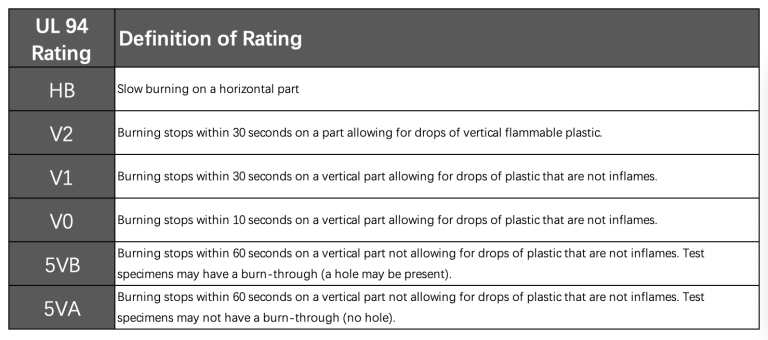

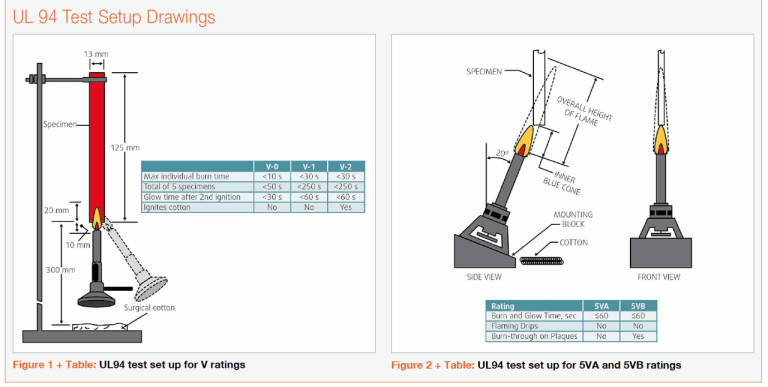

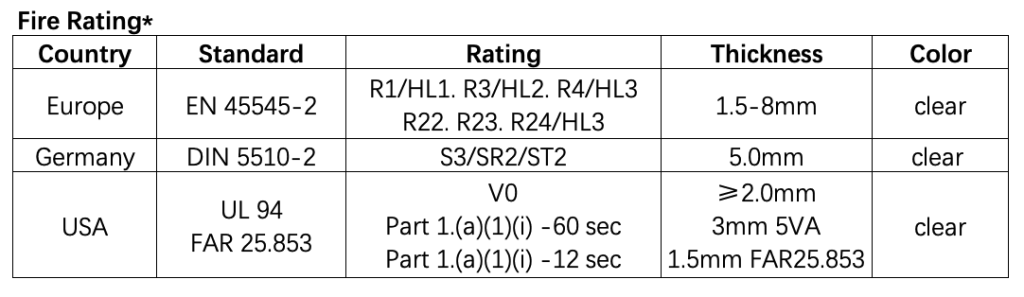

Co-extrusion with Modified Flame Retardant Materials: This approach entails introducing modified copolymers, such as polystyrene or ABS, along with halogen-free or halogen-containing flame retardants, into the polycarbonate. Polycarbonate flame resistant sheets produced using this method can meet the flame retardant standard of UL94 V-0.

Whether through additive flame retardants or co-extrusion with flame retardant materials, polycarbonate can achieve excellent flame retardant properties. Depending on the specific requirements for flame retardancy and optical performance, we can select the most optimal solution to manufacture cost-effective flame retardant polycarbonate sheets.