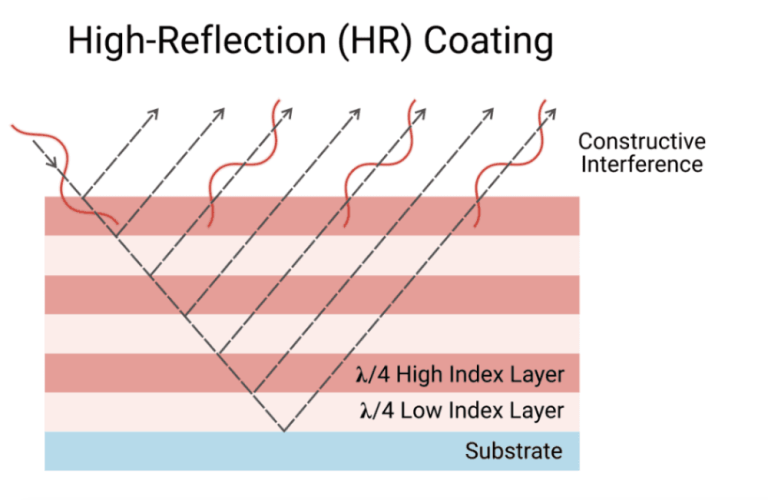

There are different technologies to the reflective resistant, which includes dip coating, spin coating, Physical Vapor Deposition(PVD), Plasma enhanced chemical deposition(PECVD) and so on. PVD, is the most commonly used method for applying anti-reflective sheets due to the strong bond between the thin film and the substrate.

Before finish an antireflective polycarbonate sheet or acrylic sheet, it starts with applying a hard coating to enhance the durability and scratch resistance of the product, especially acrylic sheet.

First, following the thermal bending process, the product may go through a silk-screen printing step to add any necessary designs, logos, or information onto the surface.

Once the silk-screen printing is complete, the product is then ready for cutting to its final dimensions.

Finally, the last step in the processing of anti-reflective products is the application of a protective film. Anti-reflective coatings can be applied as either single-sided or double-sided, depending on the intended use and application of the product. When the anti-reflective product is intended to be adhered to a screen or surface, typically only a single-sided AR (Anti-Reflective) coating combined with AF (Anti-Fingerprint) treatment is needed.