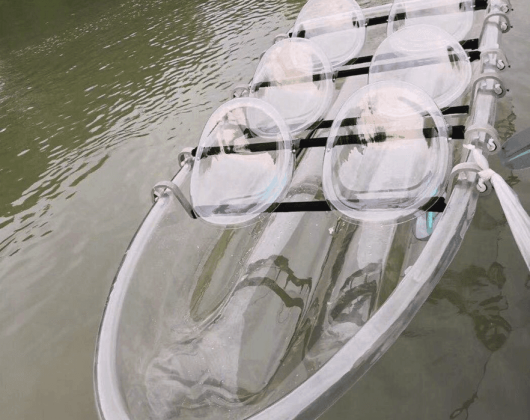

Thermoforming polycarbonate is a process where polycarbonate sheets are heated to a pliable state, allowing them to be molded into specific shapes using thermoforming mold. This method is used in manufacturing to create various products like automotive parts, electronic enclosures, packaging, and more. Thermoforming provides flexibility in design and production for a range of industries due to polycarbonate’s durability and versatility. Before we dive in the thermoforming polycarbonate guide, there are a few important questions we need to address.

Thermoforming plastic is a flexible manufacturing process utilized with different types of thermoplastic materials. Selection of thermoforming plastic relies on factors like the desired product properties, its intended application, and cost factors. Here are several primary thermoplastic materials frequently employed in thermoforming:

Polystyrene (PS):

Polystyrene is a widely used thermoplastic known for its clarity and ease of thermoforming. It is often used for packaging materials, disposable cutlery, and various consumer products.

Polyethylene (PE):

Polyethylene comes in two main types, low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is flexible and used for items like plastic bags, while HDPE is more rigid and used for bottles, containers, and pipes.

Polypropylene (PP):

Polypropylene is a versatile thermoplastic known for its heat resistance and chemical resistance. It is used for packaging, automotive components, and consumer goods.

Polyvinyl Chloride (PVC):

PVC is known for its rigidity and chemical resistance. It’s used for applications such as pipes, fittings, vinyl siding, and blister packaging.

Acrylonitrile Butadiene Styrene (ABS):

ABS is a strong and impact-resistant thermoplastic often used in the automotive industry for interior and exterior parts, as well as in consumer electronics.

Polycarbonate (PC):

Polycarbonate is transparent, strong, and heat-resistant. It’s commonly used for applications requiring optical clarity, such as eyeglass lenses, as well as for safety equipment, electronic enclosures, and automotive components.

Polyethylene Terephthalate (PET):

PET is used for packaging, particularly in the form of PET bottles for beverages and other liquids. It offers good transparency and is recyclable.

Polymethyl Methacrylate (PMMA):

PMMA, commonly known as acrylic, is used for applications requiring optical clarity and weather resistance, such as display cases, signs, and lighting fixtures.

During vacuum thermoforming, excess moisture can cause bubbling and other surface appearance defects as well as a reduction in property performance. Whilst the amount of water absorbed is not significant compared to other hygroscopic materials, it is essential that it is removed prior to forming. A hot air-circulating oven at 125°C ± 3°C is recommended. To avoid warpage, drying temperatures should not exceed 125°C and the air volume in the oven should be changed six times per hour to allow for the removal of water vapour. Overheat may cause bubble too.

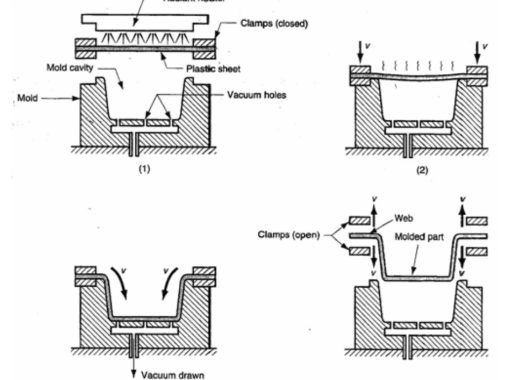

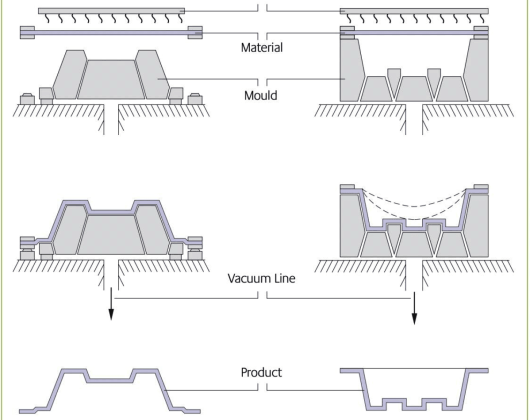

The process of vacuum thermoforming involves several steps:

Material preparation: Almost all thermoplastics have moisture absorption, with polycarbonate having a water absorption of 0.1% (WT). During vacuum thermoforming, excess moisture can cause bubbling and other surface appearance defects, as well as a reduction in property performance. While the amount of water absorbed is not significant compared to other hygroscopic materials, it is essential to remove it prior to forming.

Drying the material: A hot air-circulating thermoforming oven at 125°C ± 3°C is recommended for drying the polycarbonate panels to remove moisture. To avoid warpage, drying temperatures should not exceed 125°C, and the air volume in the oven should be changed six times per hour to allow for the removal of water vapor. Overheating may cause bubbling as well.

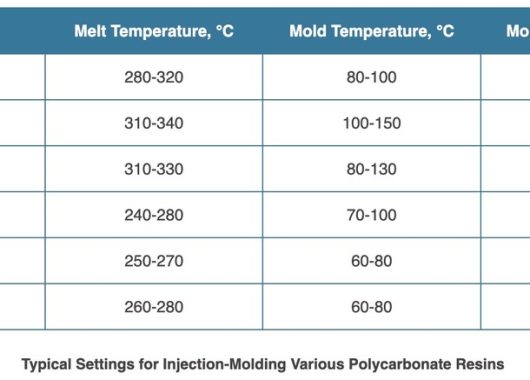

Heating the material: Once the polycarbonate sheeting is dry, it is heated to a pliable temperature. Uniform heating is vital for achieving a consistent and high-quality final product. The heating temperature varies depending on the polycarbonate material and thickness.

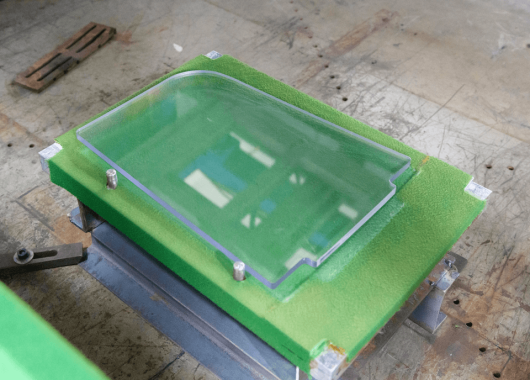

Forming the material: When the plastic sheet reaches the appropriate pliable temperature, it is placed over the mold. Vacuum pressure is then applied to assist with molding the sheet to the desired shape.

Cooling: After the plexiglass sheet has conformed to the mold, it is cooled to solidify and hold its new shape. The cooling process should be controlled to optimise the final product’s quality and reduce possible stress or warpage.

Trimming and finishing: Once the formed polycarbonate sheet has cooled, we will offer 3 or 5 axis CNC trimming or laser cutting.

By following these steps, vacuum thermoforming can successfully create a wide variety of three-dimensional forms from polycarbonate sheets, ranging from simple shapes to highly complex and large-scale designs.

If we peel off the protective film during thermoforming, then it may cause scratches or marks, but if we leave the film on, PE film may melt and leave marks too.

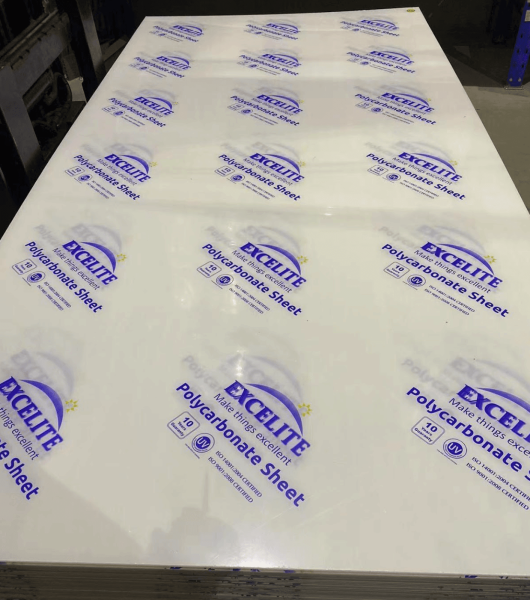

When it comes to protective film during thermoforming, there are two aspects to consider: the ease of removing the film after thermoforming, and whether the film leaves marks or not.

In general, it is recommended to keep the protective film on during the thermoforming process. This helps protect the polycarbonate sheet from scratches or marks that might occur during handling and heat forming. Contact your polycarbonate sheet supplier about the PE film before you forming.

To avoid leaving marks on the polycarbonate fabricated product, make sure the masking material is monochromatic and label-free. At Excelite, we use a special thermoformable protective film designed for thermoforming applications. With this film, you don’t need to peel off the protective layer during thermoforming, and no glue or marks will be left on the sheet. Moreover, the film can be easily removed after the thermoforming process has been completed, ensuring that your product remains protected from beginning to end.

Heating the plastic Sheet: The polycarbonate sheet is heated at a temperature between about 350 and 375°F (which is 180°C to 190°C) until it becomes pliable and soft. The exact temperature range depends on the type of thermoplastic being used and is also related to the polycarbonate thickness.

Placing the Sheet over the Mold: The softened polycarbonate sheet is then placed over a mold that has the desired shape. The mold can be made from various materials, including wood, aluminium, or composite materials. The mould can have a positive shape (the desired shape of the final product) or a negative shape (the inverse of the final product).

Creating a Vacuum: A vacuum chamber is used to create a pressure difference between the ambient air pressure and the pressure within the chamber. This difference in pressure causes the heated plastic sheet to be drawn tightly against the mold’s surface.

Forming the Plastic: As the vacuum is applied, the atmospheric pressure pushes the pliable plastic sheet against the contours of the mold. The polycarbonate sheet takes on the shape of the mold, forming the desired product.

Cooling and Solidification: After the vacuum mold plastic has conformed, cool air or other cooling methods are used to rapidly cool and solidify the plastic, allowing it to maintain the shape of the thermoforming moulds.

Ejecting the Formed Part: Once the polycarbonate has cooled and solidified, the vacuum is released, and the formed part can be removed from the thermoforming moulds. Trimming or additional finishing processes may be necessary to achieve the final product’s desired dimensions and appearance.

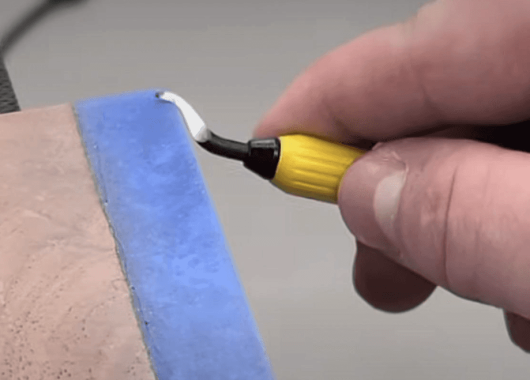

Trimming and Finishing: Smooth off rough edges using a hand deburring tool, or perform milling or drilling on a CNC machine.

For male mold forming, the internal dimensions of the part are very precise because they are in contact with the vacuum forming tool. Conversely, for female mold forming, the external dimensions of the part are very precise because their exterior comes into contact with the vacuum forming mold.

When compared to drape-forming, vacuum-forming produces shapes with much greater complexity and detail.

Tooling costs are low when compared to injection molding.

Tooling lead-time is shorter than injection molding.

Production sizes can be very small when compared to injection molding.

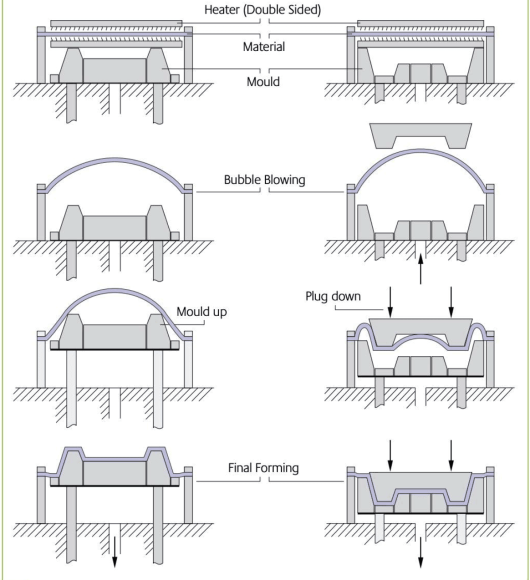

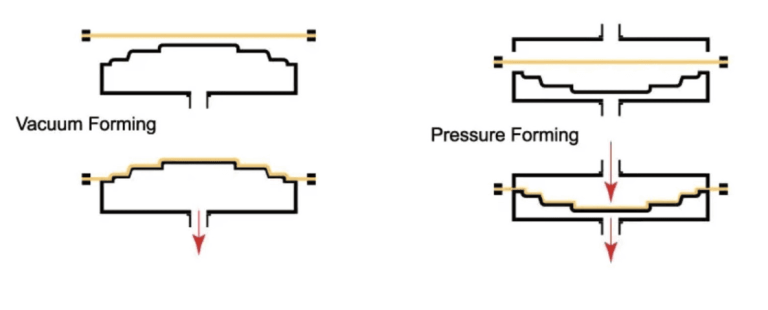

Pressure thermoforming is a manufacturing process used to shape thermoplastic materials into various forms and products. It is used to create a 2-dimensional thermoplastic sheet. Pressure forming refers to the process of using air pressure on a heated plastic sheet to create a mold or part that can exhibit high degrees of detail and texture.

Pressure forming is an enhanced version of vacuum forming. In this process, the maximum pressure exerted is up to four times higher than vacuum forming, enabling the creation of complex shapes and detailed features in the final product.

Pressure forming produces parts with good definition, often resembling the appearance of injection-molded parts.

Thermoforming Mould costs are lower when compared to injection molding.

Mold lead-time is shorter than injection moulding.

Production sizes can be much smaller when compared to injection moulding.

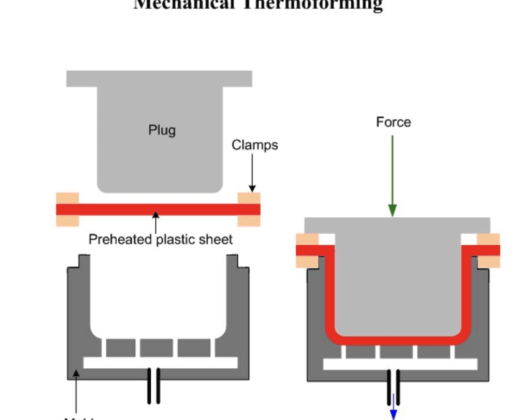

The mechanical thermoforming process involves shaping a preheated thermoplastic sheet by using direct mechanical force. A core plug (positive mold) forces the soft plastic sheet to fill the space between the plug and the negative mold. This process provides precise dimensional tolerance and surface detailing. Mechanical thermoforming is suitable for simple structures with few curves or surfaces and creates a better surface finish than vacuum thermoforming and is more precise than drape forming. It’s one of the most popular thermoforming processes. At Excelite, we use this process for products such as police shields and helmet visors.

Drape forming is a thermoforming technique where a heated plastic sheet is draped onto a mandrel designed with specific patterns. The pattern of the mandrel is pressed onto the plastic sheet to form the finished part. Since it requires limited tooling, drape forming is one of the most affordable thermoforming techniques. Additionally, the thickness of the material can be maintained, preventing any weaknesses in the final parts.

Drape forming is the simplest of all thermoforming techniques, using a single positive mold or a clamshell mold on which a heated sheet of plastic is placed. After thermal processing softens the sheet, it sags and conforms to the shape of the mold under its own weight or through slight pressure applied by an operator or the mating part of the mold. This process is well-suited for making shapes such as half cylinders, cylinders, cones, and panels with slight compound curves.

Drape-forming temperature for polycarbonate ranges from 320 to 325°F (160 to 163°C). At these processing temperatures, pre-drying is typically not required. However, it’s important to avoid prolonged cycles and overheating, as both conditions may result in moisture bubbles, mold mark-off, and pimpling in the sheet. If you want to perform drape forming with a protective film on, make sure the film can withstand high temperatures and leaves no glue or marks on the polycarbonate.

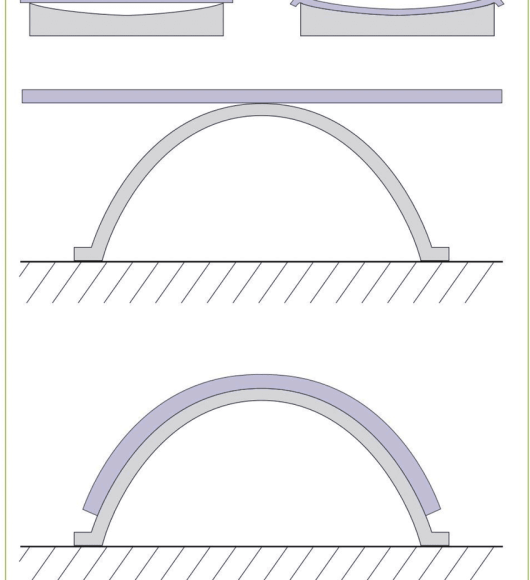

The blow forming plastic process is a free-form thermoforming technique that does not rely on molds to shape the heated plastic. The forming machine uses air jets to blast the plastic into a bubble until the final design is formed. The hot plastic is then clamped in place with a ring, and compressed air is “blown” between the bed of the press and the sheet of plastic. A bubble forms under the hot sheet of plastic and lifts the material into a free-formed dome or hemispherical shape. These shapes are referred to as “free-blown” shapes. The hot plastic can also be blown into a tool or aluminum spinning to create a more precise shape.

Thermoformed polycarbonate is the material of choice for many products, including skylights for homes, shopping centers, or offices, as well as windscreens. Because polycarbonate absorbs and retains moisture from the air, the plastic must be dried in a special oven to avoid bubbles during thermoforming.

Heating of Excelite polycarbonate sheet is a critical factor in the production of good quality thermoformed products. Sandwich-type heaters are recommended, as they provide slow, even heat on both sides of the polycarbonate sheet. These may be of the ceramic or quartz infrared type. Proportional timers, along with a controlled heating rate, are recommended, and due care and attention should be paid to the influence of power variations and air drafts. Slow heating rates will balance out hot spots and allow the sheet edges to reach the required forming temperature. Preheating of the clamping frame to 120°C-130°C is advised.

Since polycarbonate sheet cools rapidly, it is essential that final control and heating are carried out on the forming machine itself. Normal sheet temperatures range from 170°C-225°C for mechanical and vacuum forming. Optimum forming conditions depend upon part design, draw ratio, sheet thickness, and the forming technique employed.

Cooling times depend on several factors, including ambient, forming and mold temperatures, mold material, cooling system, part thickness, and design geometry. However, since polycarbonate has a relatively high heat distortion temperature, formed parts can be removed from the mold at around 125°C. Forced cooling air or water cooling is not recommended.

This article aims to share our many years of experience in polycarbonate thermoforming with you, in the hope that it will be helpful. However, the realisation of a product often involves multiple manufacturing processes, and the choice of the final process depends on the specific circumstances. The sequence of these manufacturing processes will also be determined based on practical considerations and a detailed analysis. If you have any further questions, please feel free to contact us.