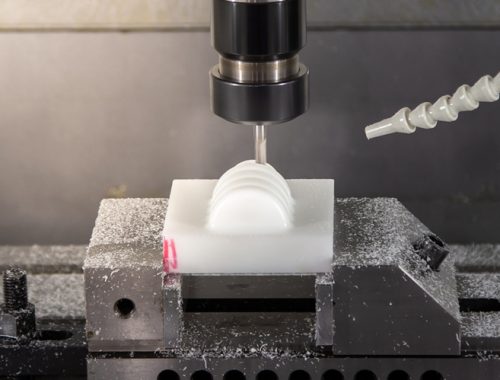

The best plastics for milling include:

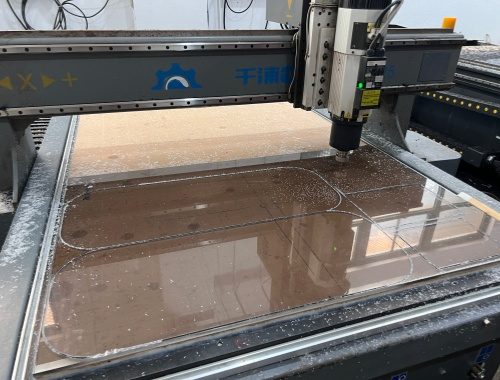

- Acrylic: Clear, easy to machine, and visually appealing.

- Nylon: Strong and wear-resistant, great for durable parts.

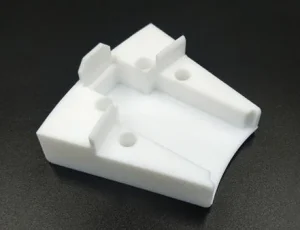

- Delrin: High strength and precision, ideal for detailed components.

- Polycarbonate: Tough and impact-resistant, suitable for various applications.

- HDPE: Lightweight and chemical-resistant, commonly used in containers.

- PETG: Strong and clear, good for transparent parts.

- PEEK: High-performance plastic for demanding environments, though harder to machine.

These plastics are chosen for their properties and suitability for different milling applications.